Start a Carpet Cleaning Business

Starting your own

Professional Carpet Cleaning business offers you a wealth of benefits.

Did you ever wanted to start your own company, be your own boss

and make money by yourself? The carpet cleaning business is good idea for a

long term profit. You might think it is easy to clean carpets, but it is not so. There is certain specified knowledge about stain removal, general carpet

cleaning and basic understanding of the limitations you equipment might have.

You need to study these aspects carefully, before offering any service.

There are three general types of carpet cleaning:

- Dry foam

carpet cleaning,

- Hybrid liquid extraction and

- The steam cleaning method

Each

of these methods has its pros and cons so if you want to offer a professional

service then you’d better stick to all of them. Most of the cleaning companies

out there use the carpet steam cleaning method, because it is the most

effective one. Anyway if you want to start a carpet cleaning business, you will

need a good plan and you must have money for start up, because the equipment

will be vital for your success.

Picking a good equipment is probably the most important part of

your business investment, so you should choose carefully. There are so many

different types of cleaning equipment and maybe as many places to buy them. There are many sites about such equipment, some of them offer

different types of discounts depending on your purchase. You will find a good

discount for your starting business for sure.

After you get your

equipment maybe it is time to start working. Oh wait, you will need clients. A

great way to popularize your cleaning services is to offer it to your friends

and relatives for a discounted price. It will also be a nice experience for you and a chance to correct mistakes that may

come along your working. We all know that people like to talk about things that

happen to them, especially if they were impressed. So this is a good way to

spread the word and get clients.

Carpet

Cleaning Methods

Hot

Water Extraction or ‘Steam’ Cleaning:

The term “ steam

cleaning” is misleading since true steam is never used to clean carpets (the

high temperature would do serious damage to carpet fibre and backing). Portable

or truck-mounted equipment is used to spray hot water and detergent solution

into the carpet pile at a high pressure and then is immediately extracted

(vacuumed out) along with the suspended soil particles. Some machines may have

rotary brushes or another agitating device to work the solution into the pile

and loosen soil.

Factors that affect the

results of this method are:

• operator skill and knowledge

• solution temperature

• spray pressure

• vacuum power

• pre-spray: spraying solution on the carpet

(particularly very soiled areas) some time before extracting

Notes: Some

“truck-mounted” units are merely portable units bolted onto the truck. The best

truck-mount machine would be powered by the truck’s engine and not your

residential electric supply. These units tend to have stronger vacuums and

remove more moisture than portable

units. Anytime a rotary

brush is used the potential for carpet fibre damage exists if the type or use

of the brush is incorrect.

Shampoo:

In this method,

detergent solution is released onto the carpet through openings in a rotary

brush, whose rotary action converts the solution into foam and works it into

the carpet. Once dry, vacuuming removes the residue containing loose,

encapsulated soil. At times, chemicals may be added to the detergent solution

to reduce odors, retard soiling, brighten colors and/or speed drying.

Notes: If the vacuuming

is not done thoroughly and effectively, the residue left in the fibres can act

as a soil magnet causing re-soiling very quickly.

Combination

of Hot Water Extraction and Shampoo:

As the name implies,

this method uses both Hot Water Extraction and Shampoo. This process is

particularly effective for cleaning highly soiled carpets, with heavy oil/soil

build -up, the process has two steps:

• Shampoo using rotary brush to loosen soil

• Hot Water Extraction using water rather than

detergent solution to remove shampoo Some units may combine both steps. It is usually more expensive because of added labor

costs.

Notes: For residential

cleaning, Hot Water Extraction on its own is usually enough to clean most

carpets and rugs with pre-spotting of highly soiled areas as required.

Foams:

A variation of

‘Shampoo’, Foam is generally applied onto the carpet, usually from aerosol

containers, and worked into the carpet with a dry sponge. Once dry, the residue

containing suspended soil is simply vacuumed away. Since foam uses little

water, there is no danger of over-wetting and the connectedcomplications. For

the same reason, this method is not as effective as the “wetter” methods!

Notes: Some foams may

leave a residue that is difficult to remove, acts as a soil magnet and may

causeproblems with subsequent wet cleaning.

Similar to ‘Shampoo’,

Bonnet cleaning employs an absorbent pad (‘bonnet’) attached to the bottom of arotary

machine. Detergent solution is sprayed onto the carpet then the rotary pad is

used to agitate and remove the soil suspended in the solution from the carpet.

Once one side of the pad gets soiled, the sides can be reversed. Some pads have

special “scrubbing strips on them. When both sides get soiled, the pad can be

replaced and later cleaned.

Spin Bonnet cleaning is

often the preferred method in maintaining large commercial office buildings.

Absorbent

Dry Compound:

A dry compound

containing detergent/ solvent is sprinkled onto the carpet and worked into the

pile using machines. The soil particles get encapsulated in the absorbent dry

compound and are removed by vacuuming. Since this method does not use any “wet”

process, there is no danger of over-wetting.

In-Plant

Cleaning:

This type of cleaning

is ideal for specialized cleaning of loose or valuable rugs. The rugs are sent

through a duster that extracts soil more effectively than routine vacuuming.

They are then washed and hung to dry in a controlled air environment. The

cleaning company may also offer a special service for repair of valuable rugs,

using special equipment.

Notes: Generally

in-plant cleaning is more expensive than other methods. One possible way to

reduce the cost would be to deliver and pick up your carpet. If you have a

valuable rug, as many oriental rugs are, check the reputation and credentials

of the cleaning company before entrusting them with your treasure.

Commercial Carpet Cleaning Machine and Equipment's

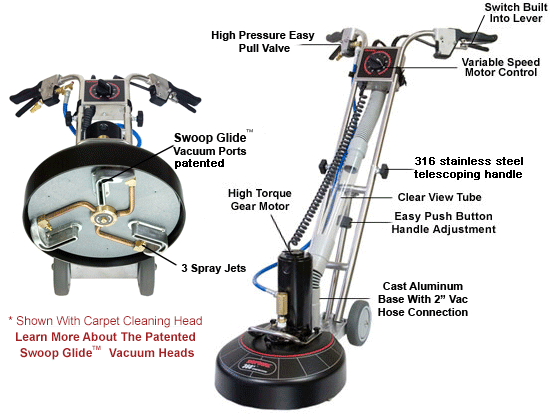

The Rotovac 360i Cleans Better With Less Effort

The Rotovac 360i is a Patented Rotary Jet Extractor that utilizes rotary vacuum heads to thoroughly deep clean carpet with hundreds of multi-directional cleaning passes. The 360i weighs only 39 lbs and is extremely easy to use as it operates in a self propelled side to side motion. Simply stated, “The 360i cleans better with less effort."

Features:

- Cleans better with less effort and leaves carpet drier than a wand

- Interchangeable heads for all type of Carpet and Tile Cleaning

- User friendly, weighs only 39lbs

- Telescoping handle for cleaning stairs and compact storage

- Durable Construction with Cast Aluminum and Stainless Steel Frame

- Unique Marketing Tool to land new accounts and generate referral business

- Industrially Engineered for Professional Use

- Made in the USA

For more detail click on below link