(273).Start a Vegetable Oil Refinery Business

Vegetable oil and fat resources are indispensable to mankind as a source of nutrient and

industrial raw materials. Crude vegetable oil obtained from various oil milling units is

further refined before use for edible purposes. Refined edible oil is a process where free fatty

acids are volatized, condensed and recovered simultaneously with vacuum de-colouring

operation.

Sometimes, refining process is limited to simple physical treatment such as heating and

filtering in regard to refining of superior quality of crude oil. Generally the cake in the oil is

separated by centrifuge, decolouring by active clay and steam deodorization at high

temperature in vacuum up to 5 mm. Hg. This is not a location specific project and can be set

up at a place where crude oil is easily available.

PRODUCTS

It is possible to refine edible oils from crude groundnut oil, sesame oil, mustard oil etc. In

this project, these three crude edible vegetable oils have been considered for refining

purposes.

MARKET POTENTIAL

The importance of edible refined vegetable oils has been appreciated and ambitious plan has

been chalked out to increase production of edible refined vegetable oils, including soya bean

110oil, by the Government of India in the previous Five Year Plans. The demand for refined

edible vegetable oils has increased in the consumer market. With growing population,

increase in the disposable income and overall trend of consumerism, demand for edible oils is

shooting up year after year. The country still imports large quantities of crude edible oil and

the Kandla port of Gujarat is active in such imports. The domestic production has gone up

during last few years but there still exists a gap between demand and supply which results

in large imports. Thus a new vegetable oil refinery has got good potential.

MANUFACTURING PROCESS

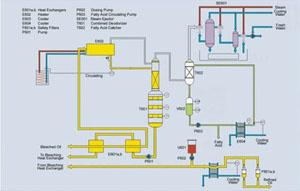

Special pre-treatment steps which are essentially a combination of de-gumming and blending

under special operating conditions, eliminate all impurities and render oil fit to be processed

at elevated temperature under vacuum. Various steps involved in refining are

(I) Super cleaning

(2) Contobleaching and

(3) De-acidification.

All these processes are very well standardized and practiced in the country since long. The

average recovery is 90%

Raw and Packing Materials

The major raw materials required are crude groundnut oil, crude sesame oil and crude

mustard oil. The state of Gujarat is famous for crude as well as refined vegetable oils with

centers like Kadi, Rajkot, Gondal, Amreli, Dhaari etc. engaged in production of various edible

oils round the year. Thus procuring adequate quantity of crude oil will not be a bottleneck.

Other materials like phosphoric acid, citric acid, bleaching powder etc would be available

from the nearby trading centres. Aluminum tins or plastic jars of different capacities along

with corrugated boxes, labels, and box strappings would be the packing materials.

Edible/Vegetable Oil Refining

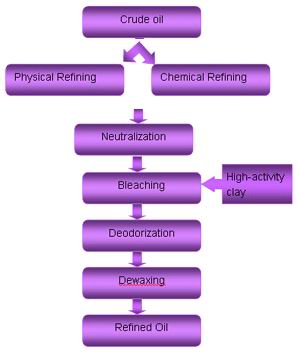

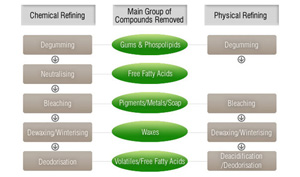

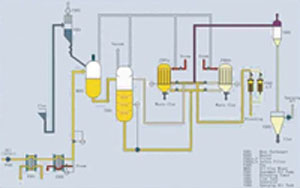

Edible/vegetable oil refining is a step by step process. Refining oil removes phospholipids, pigments, off-flavors, free fatty acids and other impurities. The entire oil refining plant process comprises degumming/neutralization, bleaching, deoderization, and winterization. Chemical refining is performed in order to remove the fatty acids from the crude oil that is extracted from the seeds. These are further neutralized with the use of caustic soda. This results in the removal of sodium soaps by batch settling or centrifugal separators. The neutral oils are then bleached and deodorized.

Edible/vegetable oil refining is a step by step process. Refining oil removes phospholipids, pigments, off-flavors, free fatty acids and other impurities. The entire oil refining plant process comprises degumming/neutralization, bleaching, deoderization, and winterization. Chemical refining is performed in order to remove the fatty acids from the crude oil that is extracted from the seeds. These are further neutralized with the use of caustic soda. This results in the removal of sodium soaps by batch settling or centrifugal separators. The neutral oils are then bleached and deodorized.Apart from chemical refining, another method that is used for edible oil refining is physical refining. Through this method, the free fatty acids are removed through the process of distillation in one stage of deodorizing. In order to come up with effective results, the crude oil should be thoroughly degummed. This is not applicable with some oil like the oil extracted from cottonseeds. All kinds of refining methods are done with the help of various equipment and machinery, and are used to refine almost all kinds of oil extracted from oil seeds like sunflower seeds, linseeds, groundnuts, sesame seeds, and mustard seeds, etc.

Physical and chemical refining is defined according to the technology used. Physical refining means the removal of gum in oil via the process of degumming, a special method for removing FFA in the process of deodorization by steam. Chemical refining, however, means chemically removing FFA (acid-base neutralization). Gum and soap produced is then separated by centrifuges.

| Features of Physical Refining

|

Features of Chemical Refining

- Excellent adaptability and fewer requirements for high oil quality

- The finished oil is consistent and stable

- Less bleaching earth necessary compared with physical refining

Process of the Oil Refining Plant

With 10 years' experience in manufacturing and exporting complete oil mills as well as a variety of oil mill machinery, KMEC is an expert in edible oil refining. In the oil refining plant, there are several steps to follow.

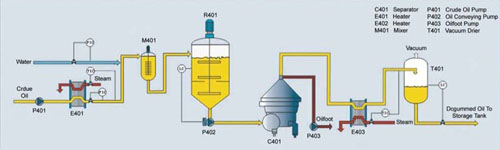

Oil Degumming Section of the Oil Refining Plant |

|

| With 10 years' experience in manufacturing and exporting complete oil mills as well as various oil mill machinery, KMEC is an expert in edible oil refining. In the oil refining plant, there are several steps to follow. |

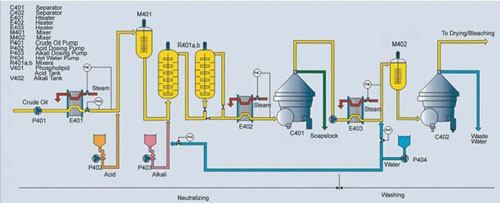

Oil Neutralization Section of the Oil Refining Plant |

|

| The pretreated oil is subjected to alkali refining. The caustic soda reacts with free fatty acids (FFA) present in the oil and forms soap stock. The soap stock is then removed by a centrifugal separator and oil is washed with water for the complete removal of soap stock. The wash water is separated out by centrifugal separators. |

Oil Deodorization Section of the Oil Refining Plant |

As the name suggests this process is meant for the removal of odor. Every vegetable oil has its own distinct natural odor. During neutralization and bleaching, unpleasant odors are imparted in the oil, thereby making it essential to remove this odor. Deodorization is essentially a process to remove odiferous matter. The operation is carried out at a high temperature by injecting open steam and maintaining high pressure at which time all odoriferous matter is distilled and removed to barometric condensers through a vacuum system. The resultant oil is odorless – deodorized oil. As the name suggests this process is meant for the removal of odor. Every vegetable oil has its own distinct natural odor. During neutralization and bleaching, unpleasant odors are imparted in the oil, thereby making it essential to remove this odor. Deodorization is essentially a process to remove odiferous matter. The operation is carried out at a high temperature by injecting open steam and maintaining high pressure at which time all odoriferous matter is distilled and removed to barometric condensers through a vacuum system. The resultant oil is odorless – deodorized oil. |

Oil Bleaching Section of the Oil Refining Plant | |

| The neutralized oil is treated with bleaching earth/activated carbon for the removal of colored pigments. The bleaching agent is filtered out in vertical pressure leaf filters. A multi-part design ensures uniform consistency in color with minimum bleaching agent requirements. The bleaching line is versatile and adaptable for all varieties of vegetable oil. |  |

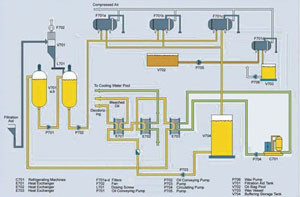

Oil Dewaxing Section of the Oil Refining Plant | |

| Oils like sunflower oil or maize germ oil (corn oil) have waxes present in them. At low temperatures these waxes give a hazy appearance to the oil. It is therefore essential to remove these waxes prior to bottling and marketing of the oil. |

Some of the equipment and packing machinery suppliers are as under:

1. Sifter International, Plot No. 83, Sector 6, Faridabad-121006

Tel. No. 2231154-4540, Fax: 2230039

2. Osaw Agro Industries Pvt. Ltd., Osaw Complex, Jagadhri Road, Ambala Cant.-133001,

Tel. No. 2699167-354-547, Fax: 2699018

3. Forsberge Agritech (I) Ltd, GIDC Estate, Makarpura, Vadodara

4. Chempro, Engg. and Consultants, 43, Sukhshine Complex, Sunrise Park, Nr. Drive In,

Ahmedabad-380054. Tel No. 26851135/9010.

5. Container Industries, C-299, Ghatkopar Industrial Estate, 72 LBS Marg, Mumbai-400080

Thank you for this useful information about Vegetable oil refinery plant in india.

ReplyDeleteNice information, Thanks for sharing.

ReplyDeleteTransformer Manufacturers In India | Transformer Manufacturers In Pune

Mectech's has established itself as a leader in extraction, refining & hydrogenation-processes -acquired over past 40 years of existence and operations in 17 countries. The company's unrelenting focus on technology itself has enabled it to establish itself as the front runner in the turnkey supply of plant & machinery for the vegetable oils and fats industry including for edible Oil Manufacturing Process.

ReplyDeleteThe crude oil obtained either from oil expeller machines or solvent extraction plant contains impurities, which must be removed to make the oil edible.The edible oil refinery plant process of removing these impurities is called refining.

ReplyDeleteNice blog.

ReplyDeleteManav Yadav

Vegetable Oil Packing Machine Manufacturers

I need to start palm oil packing machine manufacturing

ReplyDeleteNice blog..

ReplyDeleteWe are leading liquid filling machine manufacturer and supplier in india.

Liquid Filling Machine,

Vial Filling Machine,

Bottle Filling Machine

Linear Vial Washing Machine

Thanks For Good Posting If you have any queries or are you looking for Oil Skimmers then in that case, it is advisable to get connected with the expert professionals at Clear Ion Expert Pvt.Ltd.

ReplyDeleteEdible oils and fats Franchise Business

ReplyDeleteStunning post! Thanks for sharing with us.

ReplyDeleteEdible Oils Import

This comment has been removed by the author.

ReplyDeleteHello, I am Mohit Singh, I have a Company by the name of Dekentmerchandise. I read your blog and I am very thankful to you for this inforamtion. We are the cooking oil supplier in India

ReplyDeleteand provide best quality cooking oils.

We are a Professional Grease Manufacturing Plant Management company. We supply plants and machinery for Lube Oil Blending Plant, Grease Manufacturing Plant, and various other Petrochemical Industries.

ReplyDeleteThanks for sharing this blog this is very helpfull for me keep it up

ReplyDeletebuy online A2 Gir Cow Ghee in Hyderabad

best Wood pressed Edible oils in Hyderabad

We specialize in designing, engineering, and manufacturing Double Motion Grease Kettles These kettles play a pivotal role in the production of lubricating greases for various applications, including automobile, aircraft, railroad, and industrial uses.

ReplyDeleteLooking for the best A2 Gir Cow Ghee in Hyderabad? Experience the richness of traditionally hand-churned, 100% natural A2 Gir Cow Ghee made from desi Gir cow milk. Sourced ethically and prepared using the ancient Bilona method for maximum nutrition and aroma.

ReplyDelete