(328). Start a Fabric Formwork Business

Fabric formwork replaces conventional rigid forming materials such as plywood or steel panels with a thin, flexible sheet of fabric When concrete is contained by a thin fabric membrane, the flexibility of the container naturally produces a set of beautiful and structurally useful tension geometries.

In above-ground structures, fabric formwork is used to form:

- Foundation footings

- Columns

- Beams

- Trusses

- Walls

- Panels

- Domes

- Shell structures

- Furniture

- Composites

In surface and marine applications, fabric formwork is used for:

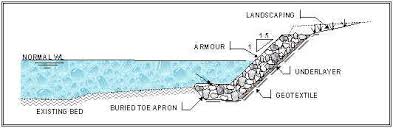

- Revetment blankets to prevent riverbank and shore line erosion

- Underwater pile jackets

FABRIC FORMWORK

Branching column formed in a geotextile form-liner.

Fabric formworks for reinforced concrete construction and architecture is an emerging technology with the capacity to transform concrete architecture and reinforced concrete structures.

The natural tension geometries given by flexible fabric membranes provide extraordinarily light and inexpensive formworks, some using hundreds of times less material than conventional formworks, and some providing zero-waste formwork systems. The flexibility of a fabric formwork makes it possible to produce a multitude of architectural and structural designs from a single, reusable mold. The use of a permeable formwork fabric produces improved surface finishes and higher strength concrete as a result of a filtering action that allows air bubbles and excess mix water to bleed through the formwork membrane.

A flexible fabric mold awakens concrete to its original wet, plastic nature by naturally producing concrete members with complex sensual curvatures. The sculptural and architectural freedom offered by this method of construction is matched by new possibilities for efficiently curved structures. Research at CAST has produced simple methods for forming beautiful and efficient beams, trusses, panels, vaults, slabs, and columns.

The Centre for Architectural Structures and Technology (C.A.S.T.) is fundamentally interested in finding simple ways to reduce the amount of material consumed in construction, while at the same time, making these constructions more beautiful. We are also committed to making these methods accessible to as many people as possible.

Fabric formwork is constructed using textile sheets (usually porous) made of synthetic fibers (typically nylon, polyesters, polypropylene) that are fabricated into containers to contain concrete during its placement and curing. The form takes the designed shape under the pressure of the wet concrete. Fabric formwork offers a fundamentally different approach to forming cast concrete because, unlike conventional formwork systems, these molds are flexible. They also offer a porous wall to the fresh concrete, improving the concrete’s strength, durability and finish quality. Further, the flexibility of the formwork membrane allows simple methods of forming structurally efficient variable section members, thus offering reductions in concrete volumes and dead weight of the cast structure. Per-square-foot material costs for fabric formwork are significantly less than most conventional formwork materials, and their low weight and volume significantly reduce storage, transport, and disposal costs. Because concrete is the most widely used construction material in the world, improvements in the economy and durability of concrete structures has significant implications worldwide. Thus, there has been increasing interest in the use of fabric formwork as an alternative to the conventional formwork. This is particularly true in situations where the cost of conventional formwork represents a high percent of the total cost of the structure or when the project conditions are difficult. More recently, inexpensive fabric formworks for casting structurally efficient variable section building components have been developed, making entirely new efficiencies for concrete construction, structures, and engineering design possible

Applications include: bridge pier underpinning, in-situ formed erosion control mattresses, pile jacketing, pipe support, marine foundations, plugging cavities in harbour work, lining sewer and effluent out fall, in-situ pile constructions, marine tunnel structures, repair of marine structures, underwater pipe encasement, lining of underground mining excavations, breakwaters, caps for solid-waste landfill, fixing earth anchors in soft soils, cooling pond and concrete canal liners, retaining walls, concrete columns used for cavity support, strip and point footings, columns (cylindrical, variable section, sculptural).. Additional applications under development include: precast architectural wall panels, precast lightweight compression-shell floor and wall panels, lightweight variable section beams.

FABRIC FORMWORK ADVANTAGES

a) Improved strength, durability and sustainability.

Studies of the properties of concrete have indicated that the common use of excess mix water to achieve workability is a serious threat to concrete quality if this excess water remains in the hardened concrete, thus reducing strength and durability. Evacuation of excess mix water, after the concrete has been placed, can be achieved successfully by the use of porous fabric formwork, by forcing excess mix water through the porous membrane by the pumping pressure and/or the weight of the concrete itself. The consequent result is the production of high quality concrete with increased compressive strength and high durability at the casting surface, which in turn increases the strength and service life of a structure, resulting in a more sustainable construction. In terms of whole-life cost accounting, fabric formwork will always offer the most cost-effective solution if the cost of repairs and maintenance of the structure is taken into account.

b) Improved surface quality. Along with excess mix water, air bubbles are also forced outside through a porous fabric formwork membrane. This results in a very high quality surface finish that is visually more aesthetically pleasing than concrete cast in conventional water-tight forms. This bug hole-free finish also reduces or eliminates the labor costs of patching or otherwise finishing exposed concrete surfaces. Additionally, since the surface shapes and textures produced in fabric-cast concrete are visually indistinguishable from the textiles that formed them, they present architecturally “softer” and more appealing surfaces and shapes. This aesthetic advantage can eliminate the substantial costs associated with the architectural sheathing of concrete structures with veneers or other covering materials.

c) Structural and architectural shape formatting.

Simple methods of forming curved structurally efficient shapes have recently been developed offering significant reductions in materials and dead weight. Architecturally and sculpturally interesting shapes, unavailable from conventional forming techniques, can also be achieved.

(d)Material Reduction: Fabric forms use hundreds of times less material than conventional rigid formwork. Concrete and steel can also be conserved by forming more efficient curved geometries.

(e)Cost Savings: Fabric forms cost far less than rigid forms due to the efficiency of the tensile-only membrane. In addition, certain fabrics can be reused many times over.

(f)Improved Concrete Quality: Permeable fabrics improve surface finish, compression, strength and impermeability by filtering air bubbles and excess mix water from the wet concrete.

(g)Waterproof Concrete: Inexpensive plastic-coated fabric forms provide a permanent waterproof shield when left on a concrete cast - useful, for example, in damp-proofing foundation footings.

(h) Beauty: Fabric-cast concrete is distinguished by its soft curves and immaculately detailed surfaces, offering unique forms of architectural beauty to concrete products and construction.

(d)Material Reduction: Fabric forms use hundreds of times less material than conventional rigid formwork. Concrete and steel can also be conserved by forming more efficient curved geometries.

(e)Cost Savings: Fabric forms cost far less than rigid forms due to the efficiency of the tensile-only membrane. In addition, certain fabrics can be reused many times over.

(f)Improved Concrete Quality: Permeable fabrics improve surface finish, compression, strength and impermeability by filtering air bubbles and excess mix water from the wet concrete.

(g)Waterproof Concrete: Inexpensive plastic-coated fabric forms provide a permanent waterproof shield when left on a concrete cast - useful, for example, in damp-proofing foundation footings.

(h) Beauty: Fabric-cast concrete is distinguished by its soft curves and immaculately detailed surfaces, offering unique forms of architectural beauty to concrete products and construction.

i) Lower formwork material and storage costs.

In many countries around the world, including most of the Middle East , wood is scarce,

requiring formwork timber to be imported great distances. In tropical climates wood quickly decays, severely limiting the multiple use of wooden formwork materials. Even in North America where wood is readily available, formwork fabrics are approximate 1/10th the cost of formwork plywood and their extremely low weight and volume significantly reduces or eliminates formwork storage and disposal costs.

j) Labour savings.

Labor costs associated with the assembly and stripping of formwork can be significantly

reduced (by 27% according to , with consequent improvements in work cycle times. The Fab-Form company claims even higher labor savings for their “Fast Tube” column

Some fabric formworks, such as pile jacket forms and fabric strip and point footing products eliminate stripping cost completely because the low-cost formwork remains with the casting.

k) Protection from “Rising Damp”.

Fabric-cast footings that retain their waterproof formwork protect the foundation structures they support from moisture penetration from below

l) Adaptable to uneven ground conditions.

l) Adaptable to uneven ground conditions.

When used to form foundation footings, fabric forms adapt to uneven or rocky ground with minimal labour compared to traditional methods.

HISTORICAL BACKGROUND

The ability to form concrete in textile containers was recognized and patented as early as

1906, with additional early patents being filed through the first half of the 20Th Century and Commercial viability of this technology was first made possible in the 1960’s by the introduction of powerful synthetic fibers such as nylon and polyester and improvements in pumping technology . More recently, the commercial use of very strong and inexpensive woven polyolefin (polypropylene and polyethylene) geotextile fabrics has further reduced the cost of fabric formwork materials. Early commercial applications were limited to geotextile civil engineering works such as cooling pond liners, revetments, landfill caps, andcoastal and river structures .In Mexico in 1951, the Spanish architect Felix Candela draped burlap fabric between timber arches to form corrugated parabolic concrete shell structures .In the 1970’s, the first strictly architectural use of flexible formworks was done by Spanish architect Miguel Fisac, who used polyethylene film sheets as formwork for precast textured wall panels .Structural, architectural, and building applications have been invented and developed since the 1980’s: fabric formed walls by Japanese architect K. Unno and, fabric foundation footing formwork and column forms by R. Fearn (Fastfoot Industries Ltd.) and systems for casting columns, slabs, panels, and beams by M. West and .Also during the 1980’s, the first engineering studies of increased concrete strength and durability in concrete cast in permeable fabric molds were begun and. In Japan , silk fabrics have been applied as a lining with timber formwork to achieve a high fair-face finish and durable concrete [29-30]. More recently the effect of filtering fabric on concrete strength and compaction has been investigated in detail by Ghaib et al. [31-33] and Abdelgader et al. In 2002 the first architectural research laboratory dedicated to fabric formwork technology was established by M. West at the University of Manitoba

The engineering properties of any fabric are determined by a combination of the material(s) and internal structure used in it’s construction, Many combinations of materials (both natural and synthetic fibers) and internal structures (woven, knitted or non-woven) are available to textile designers and engineers. Polyester, Polyamide, Polypropylene and Polyethylene are the main synthetic polymer families used as raw material to manufacture formwork fabrics .It should be noted that although these polymers are robust and powerful, they are not true elastic materials, adding factors of plastic deformation and creep to predictions of working strains. Woven polyolifin geotextiles (Polypropylene and Polyethylene) are a common choice for fabric

formwork because they combine high strength and extremely low cost, do not propagate a tear, and concrete does not adhere to them, eliminating the need for formwork release oils.

Woven Fabrics

In all fabrics most engineering properties are strongly influenced by the fabric’s internal

construction. Formwork fabrics are generally woven, with the “yarns” crossing at right

angles. The yarns running the length of the fabric are called the “warp” or “machine

direction”, while the yarns running across the width of the fabric are called the “weft” or the “fill direction”. The relative strength and density of warp and weft yarns is one of the basic determinants of textile design, though the warp direction is normally stronger than the weft direction. The yarns can be monofilaments, multifilament, or combination of both. Monofilaments yarns consist of a single element or filament, whereas multifilament yarns are composed of many separate fine filaments bundled together to form the yarn. The typical diameter of a round monofilament is about 0.5 mm, where the typical diameter of an individual filament from multifilament yarn is about 25 μm. It is found that the fabrics woven with multifilamentyarn have high strength and low extensibility when compared with fabrics woven with monofilament-yarn.The Final Shape of Fabric Form

Fabric formwork can be sewn into any configuration, size, or shape in situ or in the factory. Some fabric formwork systems use no sewing at all, and rely on standard construction connections. Most fabric formworks consist of simple, flat, rectangular sheets. Besides the shape of the fabric panels used, the variables that affect the final shape of the fabric are as follow:

a) Fabric type.

The technical characteristics of the formwork fabric directly influence the final shape of the form. The selection of the type of fabric to be used may depend upon the following

considerations: maximum magnitude of the applied forces imposed upon the fabric (fluid

pressure of fresh concrete and stress concentrations at connections), permeability of fabric (affecting water retention, and hence pressure), surface appearance/texture, elasticity – geometrical change tolerance due to extension under load of the fabric formwork, preferred method of seaming the fabrics together (sewing, heat welding, mechanical fasteners etc.), cost of the fabric.

b) Boundary conditions.

Because fabrics can only resist tension forces, many fabric formworks require some rigid

boundary conditions to restrain the fabric membrane. The exceptions to this rule are earth

stabilization formworks that are “inflated” on the ground by pumped grout and Boundary supports can be very minimal. For example: a simple rigid joint in a fabric

tube (as in the Fab-form “Fast-Tube” column form ,or a simple footing connection and a few hoist points connected to open scaffolding. They may also be more restrictive, such as an external frame, cage, or other lateral restraints. In every case the fabric will always assume a pure tension geometry between whatever boundary conditions are set by the formwork design..

c) Pre-tensioning the fabric.

Pre-tensioning a fabric membrane will increase its rigidity and stability. A mild vertical

prestress of an otherwise un-braced fabric tube column form, for example, will laterally

stabilize the column of wet concrete it contains .Deflections in horizontal panel formwork can be modulated by prestress levels given to the formwork membrane. Pretensioning of beam forms can shape a simple flat sheet of fabric so as to reduce concrete in beam tension zones

d) Ballooning phenomenon.

When concrete is placed into fabric formwork a new phenomenon appears, which is not usual in the case of rigid formwork. This phenomenon called the “ballooning phenomenon“ is a result of the internal hydraulic pressure due to the weight of the wet concrete and any pumping pressures that may be imposed. The fabric formwork essentially behaves as a membrane under fluid pressure, providing resistance through the generation of pure tension curves in three dimensions. A general principle of structural engineering holds that the most efficient means of resisting a force is by axial tension, making this system of structural resistance extraordinarily efficient as compared with the rigid frame and panels system of conventional formwork that relies, instead, on resistance through bending. Conventional bending-resistant formwork structures require significant structural depth to limit deflections to near zero, thus resulting in far greater material volumes and weight as compared with a membrane system. The deflections of a fabric formwork membrane under load not only provide the mechanism of its structural resistance, but also a unique geometric appearance quite unlike that of conventional rigid concrete molds. The understanding and control of the ballooning phenomenon, therefore, is central to fabric formwork design. Factors that affect the ballooning of fabric formwork include, according to their priority: height of concrete, and pumping pressure, area of formwork exposed to these pressures (ex. column diameter, tributary area, etc.), elasticity of the fabric, pre-tensioning levels in the fabric, concrete mix design (changes

in slump, the use of plasticized, self compacting concrete mix, etc., directly effect fluid

pressures), underwater concreting (external water pressure lowers concrete pressures on the formwork). The correlation of the above factors determines the strains in the formwork and therefore the final shape of the cast concrete, hence informing the appropriate selection of fabrics. A good design will exploit the tension curvatures that naturally result from the ballooning phenomenon to produce efficient structures. Strategic restraint of formwork deflections can be achieved by several methods including: tubular forms, exterior restraints (temporary jackets, nets, rigid frames etc.), interior “skeletons” (permanent form-ties, and ties to interior reinforcement), pre-tensioning of formwork fabrics. It should be noted that the ballooning phenomenon always occurs with fabric formwork, so the forming technique cannot be applied in structures where the bulging phenomena is strongly disadvantageous.

e) The function of the concrete structure.

Fabric formwork is extremely adaptable, and it is quite simple to alter the formwork according to a targeted function. Most forms can be achieved using simple flat rectangular sheets with no tailoring whatsoever. The final shape of the fabric formwork may be smooth when it is demanded to be smooth and may be cobbled when it is required to be cobbled. For example:

cobbled fabric forms have been used to control the laminar flow of water in canals and rivers,

and architectural applications can use cobbling to sculptural advantage. Smooth curves can

follow the natural flow of forces in a member, thus improving structural efficiency by

reducing concrete volumes as compared with flat prismatic forms

f) Concreting environment.

Environmental conditions such as turbulent water in underwater applications can have adverse

influences on the final shape of the fabric formwork. For example, it has been noticed that

fabric formwork placed in turbulent water, will be subjected to buffeting, wringing and

kneading , which may tend to wrinkle the surface of the final structure, bend it, or squeeze

out cement particle thus producing a sandy surface and making the concrete vulnerable to

abrasion. In such cases, attention must be paid to the method of immersion, the time of

immersion, and to the pore size of the fabric.

TYPES OF FABRIC FORMWORK

The most common kinds of fabric formwork can be divided into four main groups: the mattresses group, the sleeves group, the shuttering group, and the open trough group.

The Mattress Group

a) Cobbled mattresses.

Cobbled mattresses are used as revetments and characterized by an aesthetically

appealing cobbled surface. These cobbled surfaces exhibit a high coefficient of hydraulic friction and provide maximum attenuation of the hydraulic energy. These properties make it useful for erosion control applications.

a) b) c)

. Cobbled mattress (a), uniform mattress (b) articulated block (c)

b) Uniform mattress.

These forms provide a uniform surface and exhibit a low coefficient of hydraulic

friction

c) Articulated block.

Articulated block , used for supporting slopes subjected to sever scour or

consolidation, are rectangular cast-in-place mattresses in a staggered pattern, linked together

internally by reinforcing and externally by cables placed between and around the two layers of

fabric prior to mortar injection. These constructions are free to articulate according to soil and

water conditions.

The Sleeve Group

a) Pile jackets.

Pile jackets used for pile repair applications , consist of a fabric sleeve with a zipper

closure suspended around a deteriorated wooden, concrete, or steel pile. Mortar is then

pumped into the sleeve to form concrete around the old pile. Sleeves can be individually made

to meet the required shape.

b) Columns forms.

These are light cylindrical tubes made from flat rectangular sheets of fabric, though custom

and architectural profiles can also be easily achieved. They can be supported from above by

scaffolding and, or along a rigid vertical joint as in the “Fast Tube” products as

c) Concrete bags.

Closed fabric containers of any shape are used for various functions The most common are the elongated bags used to form breakwaters and dykes for shore-line protection or as slope protection against erosion . Bags are often used for foundations under water pipelines, and they can be placed over such pipelines as ballast to weigh them down .Foundation can also be easily supported by fabric form bags .

d) Fabric formwork for earth cavities columns.

The technique involves drilling holes through mine or limestone cavities below the floor of a structure and snaking a fabric tube down the hole with the assistance of a steel pipe. These fabric tubes have an inflated diameter of between 0.6 and 1.2 m. This technique solves the problems associated grouting or backfilling cavities in areas underlined by mine or limestone cavities.

The Shuttering Fabric Form

a) Concrete repair shuttering.

Used for concrete repair applications, a fabric sheet covers a deteriorated concrete surface and is fixed to the surface either by an external steel mesh or by rivets which link the cloth to the old concrete. Fresh concrete or grout is pumped between the fabric and the old concrete through a special inlet, providing a new concrete surface.

b) Cast-in-place wall formwork.

The Kenzo Unno type fabric wall formwork is composed of two layers of fabric quilted together or of a single layer of fabric on one side, quilted to a backing of rigid insulation on the other. The quilt points are held by standard form ties. The fabric formwork may be held vertically by the reinforcing steel itself, so only lateral bracing (no scaffolding) is required. Alternately, CIP wall fabric formwork may be restrained by an

exterior framework of pipes of studs connected to the form ties.

The Open Trough Group

These are flat fabric sheets supported horizontally and filled from above with concrete. This group is used to form linear members such as ribbed slabs, precast or “tilt-up” panels , precast columns and strip footings, and CIP or precast variable-section beams.

CONCLUSIONS AND FURTHER PROBLEMS TO BE SOLVED

The principle and techniques of using flexible formwork in place of conventional formwork made of timber or steel, has been established across a complete field of construction applications. In civil engineering applications, fabric formwork has been found to be a practical method of containing concrete, mortar or special grouts, both above ground and under water, and often provided the best way to overcome various difficulties and extra costs.In architectural and building construction applications fabric formwork provides a simple method of forming complex, three-dimensional, double curvature shapes, based on the naturally occurring tension geometries produced by the formwork textiles. These naturally occurring geometries provide structural and aesthetic improvements over conventional prismatic members. Additionally, the filtering action of permeable formwork fabrics provides aesthetically pleasing, high quality surface finishes as well as increased compaction and compression strength.

The following detailed statements can be formulated:

i. Fabric formwork for concrete can be applied effectively in a wide range of applications both under water and on land.

ii. Fabric formwork can be used in all climate conditions and can often replace the use of timber or steel formwork.

iii. Permeable formwork fabrics produce high quality and durable concrete; compressive strength at the surface of the mold may reach two times that of normal concrete.

iv. The subject of fabric formwork is heavily patented, though to date, there have been a

limited number of publications and reports about it.

The future development of fabric formwork calls for additional research and study in a number of areas where our current knowledge is lacking. We have identified important areas for future work as follows:

• structural interaction and adhesion between concrete and formwork fabrics,

• design tables for compressive strength achieved with specific kinds of fabric,

• optimum pore size, percentage of open area, and fabric thickness for specific kind of

structures,

• chemical reactions between concrete and specific fabrics,

• application of fabric forms as waterproofing membranes,

• fabric forms retained as permanent reinforcing (i.e. in a composite structure)

• the contribution of fabrics in resisting tensile stresses,

• optimal structural shapes based on pure tension geometries assumed by fabric

formworks, and their inversion as pure compression geometries,

• technology of reinforcement placement in efficiently curved, variable section, fabricformed beams,

• development of 3-D modelling and design/analysis software for fabric formwork and

variable section fabric-cast members.

d) Fabric formwork for earth cavities columns.

The technique involves drilling holes through mine or limestone cavities below the floor of a structure and snaking a fabric tube down the hole with the assistance of a steel pipe. These fabric tubes have an inflated diameter of between 0.6 and 1.2 m. This technique solves the problems associated grouting or backfilling cavities in areas underlined by mine or limestone cavities.

The Shuttering Fabric Form

a) Concrete repair shuttering.

Used for concrete repair applications, a fabric sheet covers a deteriorated concrete surface and is fixed to the surface either by an external steel mesh or by rivets which link the cloth to the old concrete. Fresh concrete or grout is pumped between the fabric and the old concrete through a special inlet, providing a new concrete surface.

b) Cast-in-place wall formwork.

The Kenzo Unno type fabric wall formwork is composed of two layers of fabric quilted together or of a single layer of fabric on one side, quilted to a backing of rigid insulation on the other. The quilt points are held by standard form ties. The fabric formwork may be held vertically by the reinforcing steel itself, so only lateral bracing (no scaffolding) is required. Alternately, CIP wall fabric formwork may be restrained by an

exterior framework of pipes of studs connected to the form ties.

The Open Trough Group

These are flat fabric sheets supported horizontally and filled from above with concrete. This group is used to form linear members such as ribbed slabs, precast or “tilt-up” panels , precast columns and strip footings, and CIP or precast variable-section beams.

CONCLUSIONS AND FURTHER PROBLEMS TO BE SOLVED

The principle and techniques of using flexible formwork in place of conventional formwork made of timber or steel, has been established across a complete field of construction applications. In civil engineering applications, fabric formwork has been found to be a practical method of containing concrete, mortar or special grouts, both above ground and under water, and often provided the best way to overcome various difficulties and extra costs.In architectural and building construction applications fabric formwork provides a simple method of forming complex, three-dimensional, double curvature shapes, based on the naturally occurring tension geometries produced by the formwork textiles. These naturally occurring geometries provide structural and aesthetic improvements over conventional prismatic members. Additionally, the filtering action of permeable formwork fabrics provides aesthetically pleasing, high quality surface finishes as well as increased compaction and compression strength.

The following detailed statements can be formulated:

i. Fabric formwork for concrete can be applied effectively in a wide range of applications both under water and on land.

ii. Fabric formwork can be used in all climate conditions and can often replace the use of timber or steel formwork.

iii. Permeable formwork fabrics produce high quality and durable concrete; compressive strength at the surface of the mold may reach two times that of normal concrete.

iv. The subject of fabric formwork is heavily patented, though to date, there have been a

limited number of publications and reports about it.

The future development of fabric formwork calls for additional research and study in a number of areas where our current knowledge is lacking. We have identified important areas for future work as follows:

• structural interaction and adhesion between concrete and formwork fabrics,

• design tables for compressive strength achieved with specific kinds of fabric,

• optimum pore size, percentage of open area, and fabric thickness for specific kind of

structures,

• chemical reactions between concrete and specific fabrics,

• application of fabric forms as waterproofing membranes,

• fabric forms retained as permanent reinforcing (i.e. in a composite structure)

• the contribution of fabrics in resisting tensile stresses,

• optimal structural shapes based on pure tension geometries assumed by fabric

formworks, and their inversion as pure compression geometries,

• technology of reinforcement placement in efficiently curved, variable section, fabricformed beams,

• development of 3-D modelling and design/analysis software for fabric formwork and

variable section fabric-cast members.

| |||||||||||||||||||||||||||||||||||||||||||||||||||

Thanks for sharing the excellent info!

ReplyDeleteI was just browsing for relevant blog posts for my project research and I happened to discover yours.

https://www.chinagzlaser.com/fiber-laser-cutting-machine/