(199) Start a Agro Seed Processing Plant

Agro Seed Processing Plant

| Product Code | : | 2 tonnes per hour (Paddy 26 tpd or wheat 35 tpd in 3 shifts) or 4,540 tpa. | ||

| Uploaded on | : | February 2009 | ||

1.0 Product and its applications

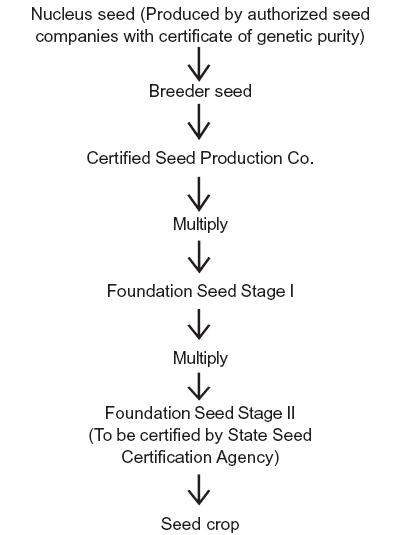

Cereal grains like paddy and wheat together constitute the main staple food in the country. Hence production of these crops ranks highest in quantity. The use of certified agricultural seeds ensures higher agricultural production. The certified seeds are produced and processed under Indian Seed Act 1996 (amended in 2002). These are sound, healthy and genetically pure with higher yields. The process consists of agricultural activity as well as processing activity under a licence from State Authority.

2.0 Market Potential

India has made phenomenal strides in production of food grains, yet there exists a vast scope for further improvement in productivity. Replacement of 10% seeds annually would ensure higher production. The farmers procure certified seeds from different suppliers. However supply is far short of the demand.. There is a tremendous scope for setting up seed processing units to meet the local demand and make the region self sufficient in food grain production.

3.0 Basis and Presumption

a) The processing plant will work for 180 days per annum on 3 shifts basis.

b) The unit can achieve its full capacity utilization during the 2nd year of operation.

c) The wages for skilled workers are taken as per prevailing rates in this type of industry.

d) Interest rate for total capital investment is calculated @ 12% per annum.

e) The entrepreneur is expected to raise 20-25% of the capital as margin money.

f) The unit would construct its own building as per Seed Certification Authority specifications.

g) Costs of machinery and equipment are based on average prices of manufacturers.

India has made phenomenal strides in production of food grains, yet there exists a vast scope for further improvement in productivity. Replacement of 10% seeds annually would ensure higher production. The farmers procure certified seeds from different suppliers. However supply is far short of the demand.. There is a tremendous scope for setting up seed processing units to meet the local demand and make the region self sufficient in food grain production.

3.0 Basis and Presumption

a) The processing plant will work for 180 days per annum on 3 shifts basis.

b) The unit can achieve its full capacity utilization during the 2nd year of operation.

c) The wages for skilled workers are taken as per prevailing rates in this type of industry.

d) Interest rate for total capital investment is calculated @ 12% per annum.

e) The entrepreneur is expected to raise 20-25% of the capital as margin money.

f) The unit would construct its own building as per Seed Certification Authority specifications.

g) Costs of machinery and equipment are based on average prices of manufacturers.

4.0 Implementation Schedule

Project implementation will take a period of 8 months. Break-up of the activities and relative time for each activity is shown below:

Project implementation will take a period of 8 months. Break-up of the activities and relative time for each activity is shown below:

| Scheme preparation and approval | : | 01 month |

| SSI provisional registration | : | 1-2 months |

| Sanction of financial supports etc | : | 2-5 months |

| Installation of machinery and power connection | : | 6-8 months |

| Trial run and production | : | 01 month |

5.0 Technical Aspects

5.1 Location

5.1 Location

Since the process consists of crop cultivation and processing activity, the plant should be located inside/near the farm wherein crop is cultivated. Availability of power, road connectivity and marketing links for supply of seed to various traders/users should be ensured.

5.2 Process of Manufacture

(a) Agricultural activity:

(a) Agricultural activity:

5.3 Quality Control and Standards: As per State Seed Certification requirements.

6.0 Pollution Control

There is no major pollution problem associated with this industry except for disposal of waste which should be managed appropriately. The entrepreneurs are advised to take "No Objection Certificate" from the State Pollution Control Board.

7.0 Energy Conservation

Only electricity is being used in the process.

8.0 Production Capacity

| Quantity | 2650 tpa paddy seed + 1890 tpa wheat seed 20 tpd |

| Installed capacity | 20 tpd |

| Optimum capacity utilization | 70% |

| Working days | 300/annum (processing activity 180 days) |

| Manpower | 28 |

| Utilities | |

| Motive Power | 15 kW |

| Water | 01 kL/day |

9.0 Financial Aspects

9.1 Fixed Capital

9.1 Fixed Capital

9.1.1 Land & Building Amount (Rs. lakh)

| Land 10,000 m2 | 09.00 |

| Built up area 1,000 m2 | 30.00 |

| Total cost of Land and Building | 39.00 |

9.1.2 Machinery and Equipment

| Mechanical dryer, elevators-3, pre-cleaner, size grader, indented centrifugal cylinder, chemical treater, automatic dosing machine, conveyor belt, bag stitching machine, misc. equipment | 22.00 |

| Erection and electrification @ 10% of machinery cost | 2.20 |

| Office furniture & fixtures | 1.50 |

| Total | 25.70 |

9.1.3 Pre-operative Expenses

| Consultancy fee, project report, deposits with electricity department etc. | 1.30 |

| 9.1.4 Total Fixed Capital (9.1.1 + 9.1.2 + 9.1.3) | 66.00 |

9.2 Recurring expenses per annum

9.2.1 Personnel

9.2.1 Personnel

| Designation | No. | Salary per month | Amount (Rs. lakh) |

| Factory manager | 1 | 10,000 | 1.20 |

| Supervisor & marketing staff | 2 | 6,000 | 1.44 |

| Office Assistant | 2 | 5,500 | 1.32 |

| Technician | 1 | 5,000 | 0.60 |

| Skilled workers | 4 | 3,500 | 1.68 |

| Unskilled workers (6 months) | 16 | 2,000 | 1.92 |

| Unskilled workers (Regular) | 2 | 2,500 | 0.60 |

| Perquisites @ 15% | 8.76 | ||

| 1.31 | |||

| Total | 28 | 10.07 |

9.2.2 Raw Material Including Packaging Materials

| Particulars | Qty(t) | Rate/t(Rs.) | AmountRs. lakh |

| Paddy 26 tpd x 120 days | 3,120 | 8,850 | 276.12 |

| Wheat 35 tpd x 60 days | 2,100 | 10,600 | 222.60 |

| Gunny bags for paddy seed, cap. 12 kg | 2,21,000 | 5.00 | 011.05 |

| Gunny bags for wheat seed, cap. 40 kg | 47,250 | 10.25 | 004.85 |

| Fungicides, stitching, marking | LS | LS | 005.63 |

| Total | 520.25 |

9.2.3 Utilities

| Power | 4.30 |

| 9.2.4 Other Contingent Expenses | Amount (Rs. lakh) |

| Repair and maintenance, building @5% | 1.50 |

| Repair and maintenance, machinery @10% | 2.42 |

| Repair and maintenance, furniture @20% | 0.30 |

| Consumables & spares! | |

| Transport & travel ! | |

| Publicity ! | 3.42 |

| Postage & stationery ! | |

| Telephone ! | |

| Insurance | 0.66 |

| Total | 8.30 |

| 2.5 Total Recurring Expenditure | Amount (Rs. lakh) |

| (9.2.1+9.2.2+9.2.3+9.2.4) | 542.92 |

9.3 Working Capital

| Recurring Expenditure for 2 months | 90.50 |

| 9.4 Total Capital Investment | Amount (Rs. lakh) |

| Fixed capital (Refer 9.1.4) | 66.00 |

| Working capital (Refer 9.3) | 90.50 |

| Total | 156.50 |

10.0 Financial Analysis

| 10.1 Cost of Production (per annum) | Amount (Rs. lakh) |

| Recurring expenses (Refer 9.2.5) | 542.92 |

| Depreciation on building @5% | 1.50 |

| Depreciation on machinery @10% | 2.42 |

| Depreciation on furniture @20% | 0.30 |

| Interest on CapitalInvestment@12% | 18.86 |

| Total | 566.00 |

10.2 Sale Proceeds / Annual turnover

| Item | Qty (t) | Rate/t (Rs.) | Amount (Rs. lakh) |

| Paddy seeds in 12 kg bags | 2,650 | 14,600 | 386.90 |

| Wheat seeds in 40 kg bags | 1,890 | 15,200 | 287.28 |

| Total | 674.18 |

| 10.3 Net Profit per year | = | Sales - Cost of production |

| = | 674.18 - 566.00 | |

| = | 108.18 lakh | |

| 10.4 Net Profit Ratio | = | Net Profit ×100 |

| -------------------------- | ||

| Sales | ||

| = | 108.18 -----------------x 100 674.18 | |

| = | 16.05% | |

| 10.5 Rate of Return on Investment | ||

| = | Net Profit ×100 | |

| ------------------------- | ||

| Capital Investment | ||

| = | 108.18 x 100 ---------------------- 156.50 | |

| = | 69.12 % | |

| 10.6 Annual Fixed Cost | Amount (Rs. Lakh) |

| All depreciation | 4.22 |

| Interest | 18.86 |

| 40% of salary, wages, utility, contingency | 9.07 |

| Insurance | 0.66 |

| Total | 32.81 |

10.7 Break even Point

= | Annual Fixed Cost x100 |

| Annual Fixed Cost + Profit | |

= | 32.81 x 100 ------------------------ |

| 32.81 + 108.18 | |

= | 23% |

11.0 Addresses of Machinery and Equipment Suppliers

1. Rohilkhand Eng. Works

Izzatnagar,

Bareilly (U.P.)

Izzatnagar,

Bareilly (U.P.)

2. Batliboi Engineers (Bangalore) Pvt. Ltd.

99/2&3, N.R.Road

Bangalore - 560 002

Narene Tulaman Manufacturers Pvt. Ltd.

Balanagar

Hyderabad - 500 037

99/2&3, N.R.Road

Bangalore - 560 002

Narene Tulaman Manufacturers Pvt. Ltd.

Balanagar

Hyderabad - 500 037

3. M/s. Kodesia Eng Works,

Izzatnagar

Bareilly

Izzatnagar

Bareilly

4. Shree Murugan Industries,

Plot No. 68/W, Hootagalli

Industrial Area, Balawadi Post

Mysore - 571186

Plot No. 68/W, Hootagalli

Industrial Area, Balawadi Post

Mysore - 571186

5. Nalanda Agro Works

Nalanda Nagar, Kurji

Patna - 800 010

Nalanda Nagar, Kurji

Patna - 800 010

6. Mac-Well Engineering Works,

14, Kartar Compound, LBS Marg

Behind State Bank

Vikroli (West)

Mumbai - 400 079

14, Kartar Compound, LBS Marg

Behind State Bank

Vikroli (West)

Mumbai - 400 079

7. Septu (India) Pvt. Ltd.

12/7, Urban Estate,

Post Box No. 4

Gurgaon - 122 001

12/7, Urban Estate,

Post Box No. 4

Gurgaon - 122 001

8. Raylon Metal Works

Kondivitta Lane

Post Box 17426

J.B.Nagar, Andheri (E)

Mumbai - 400 059

Kondivitta Lane

Post Box 17426

J.B.Nagar, Andheri (E)

Mumbai - 400 059

9. SSP (Pvt) Ltd.

13th Milestone, Mathura Road

Faridabad - 121003, Haryana

Grovers Pvt. Ltd.

223, Kaliandas Udyog Bhavan

Prabhadevi

10. Mumbai - 400 025

Macneill and Magor Ltd.

4, Mangoe Lane

Kolkata - 700 001

13th Milestone, Mathura Road

Faridabad - 121003, Haryana

Grovers Pvt. Ltd.

223, Kaliandas Udyog Bhavan

Prabhadevi

10. Mumbai - 400 025

Macneill and Magor Ltd.

4, Mangoe Lane

Kolkata - 700 001

12.0 Other Special Features

A careful selection of product mix is necessary based on the local market demand and availability of raw materials. The facilities can also be utilised to manufacture quality seeds of carrot, radish, peas, spinach, coriander, okra, other vegetables and pulses for fuller utilisation of capacity.

thanx

ReplyDeletei would have to make more christmas cards becuase next month is december already- camworks post processor

ReplyDeleteI feel all your tips are fantastic! Break it up and list it down. It always looks better and much more readable when you compose your points that way. Thanks for the tips! cam cad software for sale

ReplyDeleteThanks for sharing such amazing information.i hope you keep on

ReplyDeletesharing such kind of useful information daily.Seed and Grain Processing

i was just surfing along and came upon your blog. just wanted to say good job and this post really helped me. 먹튀검증

ReplyDeleteHi, Who is the most reliable seed processing equipment supplier in India ?

ReplyDeleteHello I am so delighted I located your blog, I really located you by mistake, while I was watching on google for something else, Anyways I am here now and could just like to say thank for a tremendous post and a all round entertaining website. Please do keep up the great work. biscotti strain

ReplyDeleteThanks for sharing such a beautiful amazing post.Thanks for sharing

ReplyDeletesuper seeder manufacturer in India

Looking for reliable SSeed Processing Machine Manufacturers ? We provide state-of-the-art seed and grain processing equipment designed for efficiency, precision, and durability.

ReplyDelete