| (221) Start a Bio Gas Making Business |

1. Energy Crisis Energy is a necessary concomitant of human existence. Although many sources of energy exist in nature, it is coal, electricity and fossil oil which have been commercially exploited for many useful purposes. This century has witnessed the phenomenal growth of various industries based on these energy sources. They have application in agricultural farms and have domestic use in one form or other. Fossil oil, in particular has played the most significant role in the growth of industry and agriculture, which would be recorded in the history of progress of human race in golden words. Whether it is flying in the air or speeding automobiles on the roads or heating and prime moving in the industry or petro-chemicals and fertilizers for farms or synthetics for daily use or cooking at home, all have been made possible by one single source - fossil oil. By now, it has penetrated so deep into the mechanism of human living that man is not prepared to accept the fact that this useful source of energy is not going to last very long. But that is the fact of life. Once fossil oil was available easily and at lower prices irrespective of its origin of supply. It has now been scarce and costly. The immediate effect of this is that the world is in a grip of inflation and rising prices. Today, energy crisis has mainly emerged from the fear that the boons of fossil oil may turn into a bane as the disappearance of fossil oil would compel the habits and practices of living of the society to change. That is the crisis and that is the compulsion for search alternate sources of energy. 2. Bio-Gas as one of the Alternate Renewable Sources of Energy It is evident that no single source of energy would be capable of replacing fossil oil completely which has diverse applications. On the other hand, dependence on fossil oil would have to be reduced at a faster pace so as to stretch its use for longer period and in critical sectors till some appropriate alternative energy sources preferably renewable ones are made available. Presently, the country is spending a fortune in importing fossil oil which can hardly be afforded for long on the face of developmental needs. Methane gas and more popularly known as bio-gas is one such alternate sources of energy which has been identified as a useful hydro-carbon with combustible qualities as that of other hydrocarbons. Though its calorific value is not high as some products of fossil oil and other energy sources, it can meet some needs of household and farms. Following table would provide an idea of comparative heat values and thermal efficiency of commonly used fuels in the household and farms. |

| |

Table-1 |

|

Commonly used fuels | Calorific values in Kilo calories | Thermal efficiency |

Bio-gas | 4713/M3 | 60% |

Dung cake | 2093/Kg | 11% |

Firewood | 4978/Kg | 17.3% |

Diesel (HSD) | 10550/Kg | 66% |

Kerosene | 10850/Kg | 50% |

Petrol | 11100/Kg | --- |

|

| |

These calorific values or heat values indicate that bio-gas can perform works similar to fossil oil in domestic cooking, lighting etc., with better efficiency depending upon the methane content in it. The bio-gas has also the potential for use in internal combustion engines used for pumping water etc. for which research and development works are in progress. Biogas, therefore, has a bright future as an alternate renewable source of energy for domestic and farm use. 3. Bio-Gas, its Production Process and Composition It would be useful to know what bio-gas is and what its properties are- (i) Bio-gas: Itmainly comprises of hydro-carbon which is combustible like any hydro-carbons and can produce heat and energy when burnt. The chemical formula of the hydro-carbon is CH4 where C stands for carbon and H for hydrogen and chemically the gas is termed as methane gas. The chemical formula of some other commonly used hydrocarbons derived from fossil oil viz. petrol, kerosene, diesel, etc. are C6H14 , C9H20 and C16H34 respectively. Unlike these hydro-carbons which are derived from direct chemical processes, bio-gas is produced through a bio-chemical process in which some bacteria convert the biological wastes into useful bio-gas comprising methane through chemical interaction. Such methane gas is renewable through continuous feeding of biological wastes and which are available in plenty in rural areas in the country. Since the useful gas originates from biological process, it has been termed as bio-gas in which methane gas is the main constituent. (ii) Production Process:The process of bio-gas production is anaerobic in nature and takes place in two stages. The two stages have been termed as acid formation stage and methane formation stage. In the acid formation stage, the bio-degradable complex organic compounds of solids and cellulose presents in the waste materials are acted upon by a group of acid forming bacteria present in the dung and reduce them into organic acids, CO2, H2, NH4 and H2S. Since the organic acids are the main products in this stage, it is known as acid forming stage and this serves as the substrates for the production of methane by methanogenic bacteria. In the second stage, groups of methanogenic bacteria act upon the organic acids to produce methane gas and also reduce CO2 in the presence of H2 to form methane (CH4). At the end of the process the amount of oxygen demanding materials in the waste product is reduced to within the safe level for handling by human beings. There are four types of methano-genic bacteria; Methano-bacterium, Methano-spirillium, Methano-coccus and Methano-circina. These bacteria are oxygen sensitive and photo-sensitive and do not perform effectively in the presence of oxygen and light. ConstituentsThe gas thus produced by the above process in a bio-gas plant does not contain pure methane and has several impurities. A typical composition of such gas obtained from the process is as follows:

|

| |

Table-2 Table-2 |

| |

| Methane | 60.0% |

| Carbondioxide | 38.0% |

| Nitrogen | 0.8% |

| Hydrogen | 0.7% |

| Carbon-monoxide | 0.2% |

| Oxygen | 0.1% |

| Hydrogen Sulphide | 0.2% |

|

| |

The calorific value of methane is 8400 kcal/ m3 and that of the above mixture is about 4713 Kcal/ m3. However, the bio-gas gives a useful heat of 3000 kcal/m3. If similar heat values are to be obtained from other sources of fuel, the equivalent quantities of those fuel have to be substantial as may be seen from Annexure-III. It is not the quantity which is so important but while bio-gas is renewable, others are not. 4. Scope of Bio-Gas Plants The basic feed material for, bio-gas plants in India has been considered to be cattle dung which is available in plenty. The estimated cattle population of 238 million in the country has the potential to produce about 1000 million tonnes of dung every year. According to an estimate (1977) of Khadi and Village Industries Commission (KVlC), bio-gas plants of average family size may provide energy equivalent to 5432 million liters of kerosene which in terms of current prices may cost well over Rs. 1000 crore per annum. Although, cattle dung has been recognized as the chief raw material for bio-gas plants, other materials like night-soil, poultry litter and agricultural wastes are also used where they are socially acceptable. In addition to combustible gas, the bio-gas plants would also be a source for conserving organic manure, rich in NPK. It is estimated that recoverable dung from 236 million cattle can add about 3.5 million tonnes of Nitrogen to the soil every year and for ensuring its conservation bio-gas plants can be very useful. The scope for bio-gas plants in India, therefore, is substantial if the benefits accruable from such plants are exploited by people living in rural areas. 5. Major Benefits of Installing Bio-Gas Plants It is estimated by the Govt. of India, Ministry of Energy, that alternative sources of energy like bio-gas plants, wind mills etc. may reduce the dependence on conventional sources of energy by about 20% by the turn of the century, provided promotional efforts are continued. Presently, the cooking media in rural areas consist of burning dung cake, fire-wood and to some extent kerosene where it is available easily. The installation of bio-gas plants would directly replace the use of above three and in saving them, following gains would be made: (i) Nearly 30% of available dung which is burnt and wasted would be recovered as bio-gas plants conserve the dung while producing bio-gas. Again, the dung after digestion in gas plant preserves more of NPK in the dung solids and cellulose which otherwise gets lost if heaped in the open. |

| |

Table-3 Table-3

Percent NPK |

| |

| N | P2O5 | K2O |

Bio-gas slurry | 1.4 | 1.0 | 0.8 |

Farm Yard Manure (FYM) | 0.5 | 0.2 | 0.5 |

Town Compost | 1.5 | 1.0 | 1.5 |

|

| |

The benefits derived from bio-gas plants in terms of manure and useful energy are illustrated at Annexure 1& II. The average NPK content of Farm Yard Manure (FYM) is about 0.5, 0.2 and 0.5 percent respectively and it may be observed that biogas slurry is rich in NPK by more than four times than ordinary dung when converted into FYM. When the country is faced with shortage of fertilizers and has to spend enormous amounts for its import, the application of bio-gas slurry can replace the chemical fertilizers to a large extent. Bio-gas slurry or FYM not only adds NPK but it proves the soil porosity and texture. These are established benefits. (ii) Second major benefit is that rural people would gradually stop felling trees. Tree felling bas been identified as one of the major causes of soil erosion and worsening flood situation. Government has started massive afforestation programme to tackle the erosion and flood situation. Continued deforestation has been causing ecological imbalances in the environment in which we live. Bio-gas plants would be helpful in correcting this situation. (iii) In rural areas kerosene is used for lighting lantern and cooking in a limited way wherever kerosene supply has been made possible. Whatever quantity is used can be replaced by bio-gas as it can be used for lighting and cooking. This would reduce the dependence on fossil oil directly and in saving foreign exchange. (iv) Lastly, the most important social benefit would be that the dung being digested in the digester, there would be no open heap of dung to attract flies, insects and infections. The slurry from digesters can be transported to the farm forapplication in the soil, thus keeping the environment clean forinhabitation. Also, gas cooking would remove all the health hazards ofdung cake orfire wood cooking and would keep the woman folk free fromrespiratory and eye diseases which are prevalent in the villages.

6. History of Technological Development, Past Achievements, Future Programme and Role of Institutional Finance History of Technological DevelopmentThe bio-gas technology is not new to India. Its experimentation started in 1940 when Dr. S.V. Desai after visiting Dadar sewage purification station at Bombay took up an experimental gas plant at Indian Agricultural Research Institute (IARI). The cattle dung fermentation followed next which was patented by Shri Jasbhai J Patel in 1951. However, the model had undergone several modifications and in 1954 the plant was named Gramlaxmi III. The same model has been propagated by KVIC in a nation wide programme since 1962. This KVIC model has stood the test of time although many institutions and individuals kept experimenting for better models and introduced several models but not good enough to completely replace the KVIC model. However, the late seventies saw the new Janata model where the difference in cost was about 20%. Even this model has not affected the popularity of KVIC model. It's designs etc. has been discussed later in this paper. Past Achievements and Future Programmes All along since 1962, KVIC was the sole agency forpromotion of bio-gas plants independent of government programme. The threat of oil embargo during the last Arab-Israel war in 1973 made the Government to include Bio-gas plants as alternative sources of energy to reduce the. dependence on fossil oil on its Vth Five Year Plan. The target set was one lakh gas plants for the plan period. However only 80,000 gas plants were reported to have been installed inspite ofthe fact that government provided 25-50% subsidy to the users. It was more vigorously pursued in the VI Five Year Plan with a target of 4 lakh gas plants. It is estimated that at the end ofVIPlan the achievement is no more than 45% of its target. The programme ofbio-gas plants are now covered under the National Biogas and Manure Management Programme (NBMMP) of Govt. of India, Ministry of Non Conventional Energy Sources. The NBMMP will be implemented with a physical target of 1.60 lakh biogas plants during FY 2003-2004. It can be noted from the above discussion that during last 21 years, the achievement has not, been appreciable. The government is now convinced that bio-gas plant technology is not a failure. However, social environment has to be more favorable for the speedier progress. For example, China has taken a rapid stride in the same field where the social environment is favorable to bio-gas technology. The Relevance of Chinese ExperienceA comparative study of India and China carried out by Centre for Application of Science & Technology to Rural Areas (ASTRA), Indian Institute of Science, Bangalore gives a striking revelation of the achievement of China in the field of bio-gas. India started the experimentation much earlier and actual programme started in 1967 where as China took to this technology only in 1970. Even after a late start, China over took India to reach anunbelievable target within a short span of 7 years. However, with persistent efforts thereafter, the Indian programme got some fillip but there is still a long way to go to tap the potential. This can be observed from the following: Table-4Year Population of Bio-Gas Plants India |

| |

| | India | China |

1973 | 8,000 | 5,000 |

1980 | 80,000 | 72,00,000 |

1998 | 27,50,000 | 69,00,000 |

|

| |

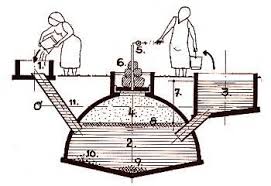

The achievement of China deserves all appreciation as they have managed to install so many numbers without much of cattle dung but with sources which are within easy reach. The daily feed in Chinese gas plants consists of 20 kgs. waste from four pigs, 4 kgs. waste from 5 humans, 6 kgs. of straw and poultry litters. All these are available with majority of Chinese families and so they have been successful in popularizing the gas plant, as feed was not a constraint. In India, rural population would perhaps not adopt such raw materials as their Chinese counterparts do. In our country. rural people are ready to handle cattle dung but not other raw materials and number of such families owning 4-5 cattle are not many. Only 20% of the household own 4-5 cattle. Unless the remaining rural families adopt raw materials like Chinese have done, very limited success can be hoped. Chinese have followed the programme with all seriousness inspite of the fact that they are self-sufficient and exporter of fossil oil. When Chinese could take advance measures to counter the future energy crisis, we should be more vigilant in taking this programme seriously. However, a word of caution is added here that since large number of plants are failing in the field, sufficient care should be taken to select the type of plant and for sound construction. Role of Institutional FinanceThe responsibility for providing technical guidance, installation, supervision and also subsidy has been entrusted to KVIC and the states by the Government who have acquired sufficient experience due to their long association with the bio-gas programme. However, it has been observed that most of the plant users fail to raise their own contribution due to lack of resources. This made the financial institutions difficult to play its role in meeting the credit requirement. During the year 1974-75 the commercial banks entered the fray. The Government has now attached top priority to the bio-gas programme in which banks have a special role to play in making the programme successful. It is in this context that bank officials would have to acquaint themselves with the technology, operations, field problems, post installation maintenance and economical and social aspects of bio-gas plants and its programme so that formulation, appraising and processing of schemes become easier. 7. Main Features of the Bio-Gas Plant On the basis of the gas holder the present bio-gas plants are classified mainly into two groups -fixed dome type or floating drum type. Both the type of plants have the following functional components: (i) Digester : This is the fermentation tank and is built partially or fully underground. It is generally cylindrical in shape and made up of bricks and cement mortars. It holds the slurry within it for the period of digestion for which it is designed. (ii) Gas holder: This component is meant for holding the gas after it leaves the digester. It may be a floating drum or a fixed dome on the basis of which the plants are broadly classified. The gas connection is taken from the top of this holder to the gas burners or for any other purposes by suitable pipelines. The floating gas holder is made up of mild steel sheets and angle iron and is required to exert pressure of 10 cms of water in the gas dome masonry and exert a pressure upto 1m of water column on the gas. (iii) Slurry mixing tank: This is a tank in which the dung is mixed with water and fed to the digester through an inlet pipe. (iv) Outlet tank and slurry pit: An outlet tank is usually provided in a fixed dome type of plant from where slurry in directly taken to the field or to a slurry pit. In case of a floating drum plant, the slurry is taken to a pit where it can be dried or taken to the field for direct applications. 8. Broad Basis of Plant Design For designing a bio-gas plant, there is a need to match the gas requirement to the feed material available so that there is a continuity of gas production and supply without interruption. For this; it is useful to know the average requirement of gas for different uses, dung produced per day and average gas production per units of different feed materials. Some basic information on these aspects are furnished in annexure I to VI. The design of a plant may be determined in the following manner: (a) Bio-Gas requirement: Make use of Annexure IV to decide the total requirement of gas per day. If we take a case where gas requirement is 3 cum, further consideration of the design may be followed as observed in the following paragraphs: (b)Raw Material Requirement : To find out the quantity of equivalent dung for production of 3 cum gas refer Annexure - V. By dividing 3 cum by 0.04 cum. which is equivalent to 1 kg of dung it would reveal the total quantity of dung required for the purpose. In this case it is 3/0.04= 75 kgs. Thereafter, refer Annexure VI to know the number at animals necessary to produce 75 kgs. of dung. (c) Digester Design : When dung is mixed with an equal quantity of water, it gives a slurry which has a specific gravity of 1.089. So the volume of slurry fed per day would be equal to (75 + 75)/ (1000 x 1.089) = 0.138m3 Therefore, for a 50 days retention plant, the volume of the digester has to be equivalent to 0.138 x 50 or 6.9 m3 say 7 m3. The recommendation of KVIC is to have a digester volume of 2.75 times the volume of gas produced per day. The commissions recommendation for the depth of the plant is between 4 to 6 m according to the size but for economical use of building materials, a depth to diameter ratio between 1.0 to 1.3 are considered ideal for all types of plants. In a floating drum plant, a continuous ledge is built into the digester at a depth 10 cm. shorter than the height of the gas drum to prevent the gas holder from going down when no gas is left in it. It helps in preventing the gas inlet being choked. It also guides the gas bubbles rising from the side of the plants into the gas bolder. In some plants slurry is fed at the bottom and removed at the top. When the digester diameter exceeds 1.6 m, a partition wall is provided in the digester to prevent short circuiting of slurry flow and increasing its retention period. Some standard dimensions of such floating drum plants are given at Annexure VII. In case of fixed dome plants, the volume of digester comes to between 1.5 times to 2.75 times the gas produced per day. Here, the higher the plant capacity, the lesser becomes the ratio of digester volume to gas produced per day. (d) Gas Holder Design: The design of a gas holder is influenced by the digester diameter and distribution of gas use during the day. For domestic plants, the gas holder capacity is kept at 60 per cent of a day's gas production and in case of laboratories, it is kept at 70 per cent of the day's gas production. In a floating drum plant, the gas holder diameter is 15 cm. less than the diameter of the digester and accordingly the other dimensions are decided. The gas holder can be given a rotary movement around its guide to break the scum formation at the top. In a fixed dome plant the dome angle is kept between 17° and 21° and it gives a pressure upto 100 cm. of water. Due to higher pressure, the diameter of gas pipelines can be reduced and the gas can be taken to greater distance. In this plant, care should be taken to provide and an earth pressure equivalent to 100 cm of water column from the top of the dome. Always use 'A' class bricks in the domes for better stability. (e) Inlet Tank : Before the dung is fed into the plant, it is mixed with water in a tank to give a solid content of 7.5 per cent to 10 per cent in the slurry. This tank also helps in removing grass and other floating materials from the raw materials to prevent excessive scum formation in the plant. This tank is connected to the digester by an asbestos cement pipe. The floor of the mixing tank is given a slope opposite to the direction of inlet pipe to help heavy inorganic solid particles to settle and get separated from the slurry. 9. Base Pre-requisites of Bio-Gas System (i) Land and Site: While selecting a site for a bio-gas plant, following aspects should be considered: (a) The land should be leveled and at a higher elevation than the surroundings to avoid runoff water. (b) Soil should not be too loose and should have a bearing strength of 2 kg/cm2 (c) It should be nearer to the intended place of gas use. (d) It should also be nearer to the cattle shed/ stable for easy handling of raw materials. (e) The water table should not be veryhigh. (f) Adequate supply of water should be there at the plant site. (g) The plant should get clear sunshine during most part of the day. (h) The plant site should be well ventilated as methane mixed with oxygen is very explosive. (i) A minimum distance of 1.5m should be kept between the plant and any wall or foundation. (j) It should be away from any tree to make it free from failure due to root interference. (k) It should be at least 15m away from any well used for drinking water purpose. (l) There should be adequate space for construction of slurry pits. (ii) Feed for gas plants: The feed for gas plants in India mainly comprises of dung from cattle. Although, quantity of dung per cattle depends upon health, age, type and many other factors, it is generally believed that, average cattle yield is about 10 kg dung per day. On this presumption, the number of cattle required for various sizes of gas plants as has been recommended by KVIC can be taken from following table. Table-5 Requirement of cattle for various sizes of gas plants |

| |

Plant Size in M3 | Minimum number of cattle required |

2 | 3 |

3 | 4 |

4 | 6 |

6 | 10 |

8 | 15 |

25 | 45 |

|

| |

However, it is advisable that assessment of dung and animal requirement may be made as per approach discussed in Sl. 8. (iii) Temperature: Temperature plays the most important role in the bio-gas production. The total amount of gas production from a fixed weight of organic waste is best when the temperature is within the messophillic range 25°C-37°C and thermophillic range between 45°C-55°C. The gas yield is maximum in the thermophillic region and the period of digestion is also reduced. It takes about 55 days in messophillic range for digestion where as it takes about 7 days in thermophillic region. (iv) Hydrogen ion Concentration: pH of slurry in the digester should be maintained between 6.8 and 7.2 for optimum gas production and this can be accomplished by maintaining proper feeding rate. pH indicates the acidity and alkalinity of the feed mixture. Any excessiveness of acidity or alkalinity would affect gas production. There are a number of ways to correct the pH if the slurry becomes acidic or alkaline. (v) Agitation: Mechanical agitation of the scum layer and slight stirring of slurry improves gas production but violent stirring retards it. (vi) Solid Content: The solid content in the slurry should be maintained between 7.5 to 10 per cent for optimum gas production. (vii) Carbon to Nitrogen Ratio: A carbon to nitrogen ratio of 20: 1 to 30: 1 is found to be optimum for bio-gas production. Carbon to nitrogen ratio of various materials is given in Table - 6 as a guide so that the C: N. ratio of bio-gas feed mixture is kept at desired level. Table 6

Carbon to Nitrogen Ratio of various materials

Sr. No. | Material | Nitrogen Content (%) | Ratio of Carbon to Nitrogen |

1. | Urine | 15.18 | 8:1 |

2. | Cow dung | 1.7 | 25:1 |

3. | Poultry manure | 6.3 | N.A.* |

4. | Night soil | 5.5-6.5 | 8:1 |

5. | Grass | 4.0 | 12:1 |

6. | Sheep waste | 3.75 | N.A. * |

7. | Mustard straw | 1.5 | 20:1 |

8. | Potato tops | 1.5 | 25:1 |

9. | Wheat straw | 0.3 | 128:1 |

* N.A.:- Data Not Available 10. Bio-gas Application and Appliances Cooking and Lighting: The main use of tbe bio-gas in rural areas is cooking. Firewood, crop residues or dung cakes are not available on regular basis and so are other conventional sources of energy like kerosene, electricity or coal etc. The other 'use is gas lamp which glows like any bright lamp. Generally, 15 running meter length (RML) of pipes/tubing are allowed in bio-gas plant schemes along with burners and lamps for schemes financed by banks. (i) Dual Fuel Engines: This is a recent appliance where certain modification of air intake system helps carburation of bio-gas to run the diesel engines. It is well known that diesel engine has wide application in rural areas from irrigation to any stationary operations and these engines can be converted to dual fuel ones. This dual fuel engine is in a position to make use of about 70% bio-gas and 30% diesel. The economy of running dual fuel engine by bio-gas is undisputable but it has certain operational difficulties. The main problem is that while bio-gas plants are located near the house, the running of the diesel pumpsets are required in the fields. As such it is impractical and technically unsound to provide long gas pipes to connect the gas plant with the diesel engines in the field. Another aspect that prohibits the use of bio-gas in diesel engine is that it requires larger gas plants at least 8-10 cum, so as to enable a 1ow 3 HP diesel engine to run for 4-5 hours a day. And often the users prefer the sizes of 2-4 cum gas plants as number of cattles are not many. However, considering large bio-gas plants hold the key to economical operation of dual fuel engines, in future one may see its wide spread application when many such gas plants come into existence. (ii) Refrigerations, Incubators and Water Boilers : There are other applications of bio-gas such as refrigerators, incubators and water boiler, Experimentation in this regard has been going on in some R & D centres whose results are awaited before they become common application items. Average requirement of bio-gas for these applications has been. shown in Annexure IV for giving an idea of the quantity of gas consumed by these appliances. (iii) Research and Development in Application of Bio-Gas: Unless ways and means are found for diverse application of bio-gas, it may not receive the appreciation in deserves. Community bio gas plants have been mooted to provide cooking gas, street light and drinking water through pumping. Government of India had proposed during 1983-84 to install 500 community gas plants on pilot basis and study their feasibility for running on cooperative basis. The results may be helpful in spreading similar plants to other areas. Besides, many institutions/individuals in the country have attempted to provide alternative gas plant designs and some 30 designs have been tried so far. Yet the KVIC design and Janata Model are the two which are not only but are recognized by the financing institutions as standard designs and this status would be maintained unless better designs come as replacements. In certain parts of the country use of night soil and connecting latrine to bio-gas plants have already found its social acceptability. However, in most part of the country it is still not socially accepted and when it finds its social acceptability, it would ensure a regular supply of feed besides improving sanitation in rural areas. 11. Implementation of Schemes It was stated earlier that the bio-gas schemes have been recognized as priority schemes under the new 20 point programme of the government. In order to expedite formulation of schemes and their implementation, government has strengthened the state and district nodal agencies with adequate staff.. Besides this agency Khadi and Village Industries Commission (KVIC) is also helping the banks in formulating the schemes and also in installation and operation of gas plants upto the running stage. They are technically equipped to undertake the field work. They are also responsible for releasing the subsidy to the extent of 25-75% of the total amount depending upon the type of beneficiaries. Scheduled castes and tribes are entitled for higher subsidy. These subsidies are declared by the government from time to time. Central government also provides subsidy for repairing defective plants. The banks process the individual cases and provide the loan amount directly to the material supplier or contractor. There are approved contractors who supply the main components and material under orders from implementing agency and loaning bank. The procedure has been systematized under the National Bio-gas and Manure Management Programme (NBMMP). The unit costs of bio-gas plants vary from district to district because of local taxes and transport costs and also for variation in site conditions which include soil, sub-surface water etc. KVIC does announce the unit costs of bio-gas plants of various sizes of their model from time to time for major regions which can be taken as the bench mark of unit costs but the actual unit costs may sometimes differ from KVIC rates and in such cases sponsorers of the schemes should provide detailed estimates of costs of material and labour. For simplifying the scrutiny of unit costs, National Bank has prepared a proforma as shown in Annexure VIII for completion by the sponsoring agencies through the help of local KVIC representatives and other local bodies associated with the implementation of schemes. However, in view of the size of the programme, National Bank now fixes unit costs for all plant models taking into account the approved schedule of rates. Besides, National Bank has also circulated a check list (Annexure IX) which all the banks should complete in order to make sure that all the requisite, information has been furnished in the scheme and. that National Bank clears the scheme without seeking any further clarification. Recently, bio-gas plants have been covered under banking schemes to give a further boost to the programme. 12. Field Problem in Implementation and Operation As has been observed so far that inspite of bio-gas plants having good potential to serve as one of the alternative sources of energy in the midst of energy crisis, the progress made in installing some 1,65,000, bio-gas plants during 1ast 21 years is not appreciable enough when we see China's progress of installing 12,00,000 plants within 7 years period. This strengthens the view that bio-gas has a better chance of success in our country than many other countries in the world where all the basic pre requisites are present. Especially, when a fossil oil sufficient country like China can feel the urgency, we should feel greater need for it. Unfortunately, we are not realizing the consequences of delaying the adoption of bio-gas plants at present. The government's determination to give fillip to the development of renewable energy sources throws a challenge to all concerned agencies who have to ensure that field problems are overcome and biogas projects are effectively implemented. The field problems and operational difficulties have been mostly identified and are known toimplementing agencies and banks should take special note of it. (i) The field problems are mainly technical, socio-economic and organizational in nature. To overcome the technical difficulties and to run the gas plant effectively, KVIC has introduced some 'Dos' and 'Donts' see Annexure X, which if followed can take care of most of the technical problems of existing models of bio-gas plants. However, there is a dire need for improving the models for easy handling, installation, operation and gas use and hence the scope of R & D is abundant in this field. (ii) The socio-economic problems are somewhat sensitive and needs to be dealt with much care. In the first place, there are very few farmers who consider bio-gas as a priority in the face of several other requirements like food, cloth, medical attention, education, social obligations etc. Besides, the cost of the minimum size of gas plant even after subsidy is considered high from the view point of a rural man. There, is a need to develop a low priced bio-gas plant. The models should be such that frequent repairing and maintenance are not needed. Then there are problems of dung collection. Often, the dung is not available in adequate quantities when the cattles are free grazing type. To overcome such difficulties the collection of night soils, poultry litters etc. can be very useful. For that aggressive extension work will have to be carried out to educate the people and remove social stigma on handling of night soil. In China, there is no such social stigma attached to the handling of night soil. That is the reason of their success. Amongst the other problems, non-availability of adequate space at the back-yard of houses is an important one as most of the villages, have clustered houses. (iii) There are some lapses on the organizational side also. The extension agencies often fail to communicate the true benefits to the users. Now, since each district nodal agency is provided with technical and other supporting staff, promotional work should get a boost. During the course of discussion with several state implementing agencies, it was revealed that target oriented approach has proved detrimental to the cause of bio-gas programme. Instead, only those potential areas where the programme can be successful should be adopted for implementation. It is also necessary to assess the need for fuel and manure of the individual cases in a scheme area before a programme is envisaged. One dispute which always crops up in the organizational side is the release of subsidy by the state govt. / KVIC and the time taken by banks to sanction the loan amount. It would be useful to come to some understanding with agencies responsible for releasing subsidies for speedy clearance of schemes so that the implementation does not get delayed. Most of the schemes and their formulation should involve the funding agencies from the very beginning so that no further need for clarification may arise. It may be pointed out that govt. desires that banks may take more initiative to coordinate the various activities and if necessary, an inter-agency coordination committee should be set up to ensure speedy disbursements. Banks have been also instructed that mortgaging of land or asking for securities should not be insisted upon for any bio-gas programme. This may lead the banks to break away from conventional banking procedures and therefore is a new challenge to the banking sector which may have to operate in circumstances where securities etc. may have to be overlooked. 13.Techno-Economic Feasibility Techno-economic feasibility is an important aspect which needs to be examined from time to time. The economics of operation, cash flow and other financial exercises are not the objective of the discussion here. However, it is necessary to understand the mechanism of techno-economic exercise particularly those technical assumptions that comprise the techno-economic feasibility. A sample calculation of the economics of 4 cum capacity floating drum bio-gas plant in placed at Annexure XI for guidance. (i) Gas Plant Size: Assessing the exact gas requirement per day is very important and therefore, efforts should be made, to ensure that whatever size is chosen, there are no wastage of gas. Otherwise it would be uneconomical to install a gas plant. It may be noted that gas production is a continuous process and every day fresh quantity of gas is available for consumption. If one fails to make use of the available gas then any assumption on savings, on account of consumption of gas would lead to misleading Benefit-Cost-Ratio (BCR) (ii) Capital Cost of Gas Plants and Cost of Operation: Although, the programme is subsidized, the cost of gas plants are considered high by the beneficiaries. A 4 cum gas plant costing Rs. 4000/- may mean monthly expenditure of Rs.40/- to Rs. 50/ if we assume a flat rate of interest on the capital be 10% without the subsidy and Rs. 20/ -to Rs. 25/-, if 50% is subsidized. Rarely, people in rural areas spend such amount in cash for domestic cooking. However; when manurial value is taken into account the gas plants show certain benefits in addition to its social benefits. Still there is a need to make a comparative study of the existing practice of cooking and lighting in rural areas and the actual cost incurred on them and if the bio-gas use can lead to direct savings. Unless the benefits are demonstrated, it would be difficult to promote the bio-gas plants in the country. (iii) Manural Value of Digested Dung : The techno-economic feasibility would not be complete unless the importance of manural value is understood properly. A notional value of the dung is generally assumed in terms of its heat value vis-a-vis quantity and cost of kerosene replaced at it its prevailing prices and in terms of NPK obtained after digestion. The main consideration for this is that the value of dung increases several times due to proper preservation of available NPK in the digested solids. In working out economics, a definite value of such dung is assumed in terms of its NPK content. However, the dung containing NPK is not saleable like chemical fertilizers 'because of ignorance of the' beneficiaries and its volume. The difference between the two is that while chemical fertilizers can be readily applied and instantly assimilated in the plants, the digested dung, requires time for assimilation in the soil. So far, manure is not looked upon as a cash return, particularly, after the preservation of Nitrogen due to digestion. But the fact remains that this manure is of cash value which a borrower can realize by applying it in his own farm and by reduced application of chemical fertilizer. This would add to his savings. This aspect requires to be communicated to the borrowers so that they may find economics of operation of bio-gas plant rational. 14. Summary 'Energy Crisis' has engulfed almost every country in the world, including comfortably placed energy sufficient countries. The main cause is depleting fossil oil reserves. It is deepening with each advancing year. It is not far when era of automobiles and aeroplanes may come to an end unless suitable alternatives are found to replace the fossil oil. However, such areas of use of fossil oil like domestic cooking, lighting etc., where alternatives are available should be replaced without further delay so that precious fossil oil could be saved for longer and critical uses. Bio-gas is one such source which is renewable and can reduce the dependence on fossil oil to a considerable extent. The by-product of bio-gas production is manure, rich in NPK which has the capacity to improve soil fertility food production and reduce import of chemical fertilizer which currently drains the large amount of foreign exchange. Bio-gas production technology is simple and has proven successful in India. It has abundant scope in the country where tropical environment and large cattle population providing ample dung favour installation of large number of bio-gas plants. Experience of the last 34 years where by some 1.65 lakh plants have been installed .are not encouraging as compared to the achievements of a fossil oil sufficient country like China, which has installed about 8 million plants within a decade. In India government has provided subsidy and organizational support and has included it in the new 20 point programme to encourage the rural people to adopt the technology and banks are supporting the programme by extending the loan required by the borrowers. One aspect, which is of particular interest to the banks, is when other sources of fuel become costly, the bio-gas plants would have its own pay-back capacity without even the govt. subsidy. That time is not far when this sector may provide better opportunity for banking because of its self-dynamic nature of development. For this reason, banks have to be in touch with its developing technology to work out their economic returns from time to time and be prepared to extend necessary financial support in whatever measure they may be required. |

| |

Annexure - I A tone of fresh cattle dung provides the following benefits through a Bio-Gas plant |

| |

1. Manure * 1.1. Fresh dung contains 80% moisture. One tonne of fresh dung gives 0.2 tonne of dry dung. 1.2. One tonne of fresh dung gives 240 kg. of manure. 1.3. Manure contains 1.6 % Nitrogen. One tonne of fresh dung gives 3.84 kg. of Nitrogen. 1.4. Manure contains 1.55 % Phosphorous. One tonne of fresh dung gives 3.72 kg. of Phosphorous. 1.5. Manure contains 1 % Potash, One tonne of fresh dung gives 2.4 kg. of potash. 1.6. Fresh dung contains 16 % organic solids. Digestion in a bio-gas plant converts 40 % organic solids to gas. One tonne of fresh dung after digestion gives 96 kg, of Humus. 2. Useful Energy **

|

| |

| |

ANNEXURE – II Potential of Bio-Gas Plants in the Country and in Village from Cow Dung1. Energy potential in the country 1.1. 22 x 106 animals in the country x 3.18 kg dry dung/day x collection efficiency = 5.38 x 108kg dry dung/day 1.2. 5.39 x 108 kg dry dung/day x 365 days/yr. = 1.967 x 1011 kg dry dung/yr. = 196 x 106 tonnes dry dung/yr. 1.3. 5.39 x 108 kg dry dung/day x 0.19m3 gas/kg dung = 1.02 x 108 m8 gas/day 1.4. 1.02 x 108m3gas/day x 4.698 K Wh/m3 kWh/day 4.791 x 108 kWh/day 1.5. 4.791 x 108 kWh/day x 365 day/yr. =175 million MWh/yr. 1.6. 1.02 x 108m3gas/day x 365 days/yr. x 62.00 x 102 kerosene per m3 gas. =23.08 billion litre kerosene

2. Manure Potential in the Country per year 2.1. 196 x 106 tonnes dry dung/yr. x 1.2 tonnes manure/tonne dry dung = 235 x 106 tonnes manure/yr. 2.2. 236 x 106 tonnes manure/yr x 0.016 tonne N/tonne manure = 3.76 x 106 tonnes N/yr 2.3. 3.76 x 106 tonnes N/yr : 2.1 tonnee N/tonne naphtha =1.76 x 106 tonnes naptha /yr. 3. Energy Potential in a Village. Considering overall collection of 100 kg. of dry dung per day in a village of 500 persons. 3.1100 kg. dry dung/day x 0.19m3 gas/kg dry dung x 4.698 kWh /m3 = 89.26kWh /day

4. Manure Potential in the Village 4.1 109 kg. dry dung/day x 1.2 kg. N/kg manure/kg dry dung = 120 kg. manure/day 4.2 120 kg. manure/day x 0.016 kg N/kg manure. =1.92 Kg. N/ day =700 kg. N/yr. 4.3 700 kg N/yr. x 5 kg. food grains/kgN = 3.5 tonnes food grains/yr. |

| |

| |

ANNEXURE – III

Equivalent Quantity of Fuel for 1 m3 of Bio-Gas

Name of the fuel | Kero-sene | Fire-wood | Cow-dung cakes | Char-coal | Soft coke | Butane | Furn-anceOil | Coal gas | Electricity |

Equivalent quantities to 1 m3 of Bio-gas | 0.620 | 3.474 kg | 12.296 kg | 1.458 kg | 1.605 kg | 0.433 kg | 0.4171 | 1.177 m3 | 4.698 kWh |

|

| |

| |

ANNEXURE -IV Bio-Gas Requirements

| SL. No. | Use | Quantity requirement |

1. | Cooking | 336 - 430 1/ day / person |

2. | Gas Stove | 330 1/ hr /5 cm burner |

| | 470 1/hr/10 cm burner |

| | 640 1/hr/15 cm burner |

3. | Burner Gas Lamp | 126 1/lamp of lighting equivalent to 100 watt filament lamp. |

| | 70 1/hr/1 mantle lamp |

| | 140 1/hr/2 mantle lamp |

| | 1691/lir/3 mantle lamp |

4. | Dual fuel engine | 425 1/hp/hr |

5. | Refrigerator | 100 1/100 litres capacity |

6. | Incubator | 80 1/100 litres capacity |

7. | Water boiler | 110 1/1 litre of water. |

ANNEXURE - V Average Maximum Bio-gas Production From Different Feed Stocks

Sl. No. | Feed Stock | Litre /kg of dry matter | % Methane content |

1. | Dung. | 350* | 60 |

2. | Night-soil | 400 | 65 |

3. | Poultry manure | 440 | 65 |

4. | Dry leaf | 450 | 44 |

5. | Sugar cane Trash | 750 | 45 |

6. | Maize straw | 800 | 46 |

7. | Straw Powder | 930 | 46 |

* Average gas production from dung may be taken as 40 lit/kg. of fresh dung when no temperature control is provided in the plant. One Cu. m gas is equivalent to 1000 litres. ANNEXURE-VIAverage Dung Night-Soil Production

Sr. No. | Living Beings | Quantity of Dung / Night Soil produced (kg/day) |

1. | Cow, Heifer | 10.0 |

2. | Bullock | 14.0 |

3. | Buffalo | 15.0 |

4. | Young bovine | 5.0 |

5. | Horse | 14.0 |

6. | Horse, young | 6.0 |

7. | Pigs, over 8 score | 2.5 |

8. | Pigs, under 8 score | 1.0 |

9. | Ewes, rams and goats | 1.0 |

10. | Gees and Turkeys | 0.2 |

11. | Lambs | 0.5 |

12. | Duck | 0.1 |

13. | 10 hens | 0.4 |

14. | Human beings | 0.4 |

Note : For free grazing animals the availability of dung may be taken as 50 per cent of the amount given in the table. |

| |

|

| |

All dimensions are in mm

Plant Size | D |

| D2 | L1 | B1 | F1 | h1 | h2 | h3 | h4 | h5 | h6 | h7 | R | GATE |

2 | 2750 | 2500 | 2370 | 850 | 610 | 580 | 680 | 765 | 810 | 680 | 1575 | 1345 | 520 | 1610 | 610x610 |

3 | 3100 | 2950 | 2720 | 1216 | 900 | 746 | 846 | 828 | 880 | 845 | 1710 | 1575 | 590 | 1865 | 610x610 |

4 | 3610 | 3400 | 3000 | 1372 | 950 | 825 | 1005 | 990 | 854 | 1005 | 1845 | 1715 | 640 | 2080 | 610x760 |

6 | 4110 | 3890 | 3420 | 1620 | 1380 | 660 | 840 | 1290 | 1025 | 840 | 2315 | 1950 | 735 | 2360 | 610x1000 |

|

| |

|

| |

ANNEXURE - VII B Dimensions of Floating Drum Type Bio-Gas Plants

All dimensions in centimeters |

| |

Dime-nsio-ns | Plant capacity , m 3 |

| For 30 Days Retention Period | For 40 Days Retention Period | For 55 Days Retention Period |

| 1 | 2 | 3 | 4 | 6 | 8 | 10 | 1 | 2 | 3 | 4 | 6 | 8 | 10 | 1 | 2 | 3 | 4 | 6 | 8 | 10 |

A | 120 | 135 | 160 | 181 | 220 | 240 | 275 | 120 | 135 | 160 | 180 | 220 | 240 | 275 | 120 | 135 | 160 | 180 | 220 | 240 | 275 |

B | 157 | 187 | 202 | 212 | 212 | 242 | 232 | 177 | 257 | 277 | 292 | 292 | 332 | 317 | 227 | 327 | 377 | 427 | 427 | 477 | 477 |

C | 170 | 95 | 110 | 135 | 135 | 125 | 115 | 170 | 165 | 185 | 200 | 200 | 200 | 200 | 170 | 220 | 270 | 320 | 320 | 345 | 345 |

D | 112 | 70 | 70 | 70 | 70 | 70 | 70 | 112 | 110 | 100 | 90 | 90 | 90 | 120 | 112 | 175 | 180 | 180 | 210 | 210 | 205 |

ANNEXURE - VIII |

| |

Cost Estimate for Bio-Gas Plants Model : Capacity : |

| |

Sr. No. | Item | Quantity | Rate/Unit Quantity | Cost |

1. | Earth Work |

| |

|

2. | Bricks |

| |

|

3. | Cement |

| |

|

4. | Sand |

| |

|

5. | Morrum/ Stones |

| |

|

6. | Skilled labour days for construction of plant |

| |

|

7. | Unskilled labour days for plant construction |

| |

|

8. | A.C. Pipes (when required) |

| |

|

9. | Gas holder |

| |

|

10. | Pipes & fittings with. sizes |

| |

|

11. | Gas burner/chullah |

| |

|

12. | Gas lamp (when required) |

| |

|

13. | Any other item, if required with specific details |

| |

|

14. | Transportation charges |

| |

|

|

| |

* The rates should be as per the State Government schedule of rates or approved district schedule of rates.

ANNEXURE -IX

CHECK LISTSchemes for installation of Bio-Gas Plants (To be completed by the Senior 'Executive/Officer forwarding the Scheme) NOTE : Ticks in boxes to signify that the details of relevant information, as per guidelines circulated by NABARD, are furnished in the scheme on the following aspects: |

| |

1. | Objectives |

2. | Whether the scheme area has been specified? |

3. | Whether the financing bank and its branches have been, specified? |

4. | Whether the scheme has been approved by the competent authority? |

5. | In case of schemes through the State Land Development Bank, whether the State Government's clearance has been obtained? |

6. | Background information and the status of the , implementation of such schemes in the area, percentage failure of plants installed in the past in the area and the reasons for failure - Results of evaluation of the programme, if any, done. |

7. | Criteria for selection of the beneficiaries and the size of the plant having regard to adequacy of land for plant and connected pits, distance from the point of use of manure, nearness to cattle sheds, number of cattle. owned, availability of water for use of plant, etc. |

8. | Designs, specifications and quality of material for different sizes of gas plants |

9. | Designs, specifications and quality of material for different sizes of gas plants |

10. | Financial returns: Estimated benefits for different sizes of plants, financial rates of returns and repaying capacity. |

11. | Lending terms : rate of interest, loan maturities (inclusive of grace period), down payment, nature of security, source and extent of subsidy, if any, available. |

12. | Arrangements for fabrication of the gas holder, frame and burners and quality control measures. |

13. | Arrangements for procurement of the equipment and supply to the beneficiaries. |

14. | Agency providing the technical support: Whether certificate from the competent agency has been obtained regarding the technical feasibility of the programme? |

15. | Availability of staff for technical appraisal of each proposal and furnishing technical certificate on completion and installation of the plant. |

16. | Arrangements for supervision and monitoring of scheme implementation. |

17. | Government support : (a) Technical guidance (b) Whether necessary budget provision has been made / proposed if any, required ? |

|

| |

ANNEXURE - X

Do's and Dont's for floating Drum Plant |

| |

| DO's |

| DON’T's |

1. | Select the size of Bio-Gas plant, depending on the number of animals you have. | 1. | Do not install a bigger size Bio-gas plant if you don't have sufficient dung for it. |

2. | Install the Bio-Gas plant at a well as the animal shed. Under normal conditions, the distance between the gobar gas plant and the kitchen may be kept at 9.1 mtrs. (30 ft.) in the case of a 2 cum. (70 cft.) plant, 13.7 m. (45 ft.) for a 3 cum. (105 cft.) plant, 18.2 m (60 ft), for a 4 cum. (140 cft.) plant, 22.8 m (75 ft.) for a 8 cum. (28.0 cft) plant, and so on. | 2. | Do not install the Gobar gas plant at a distance more than that recommended. Otherwise you will have to provide additional pipe-line which will add to your cost.

|

3. | Make sure that the Gobar Gas plant is installed in an open place, and gets plenty of sunlight during the day time round the year. | 3. | Do not install the gobar gas plant under a tree, inside the house or in any other shady place. |

4. | After construction, the digester should be "cured" for 10 to 12 days. | 4. | Do not use the digester immediately after construction, without proper curing otherwise cracks will develop. |

5. | The outer side of the digester wall must be compacted with soil. | 5. | The soil around the outer wall of the digester should not be loosely compacted; otherwise the digester may get damaged due to slurry pressure. |

6. | Feed the Gobar Gas Plant with cattle dung and water mixed in the right proportion : add 4 parts of dung to 5 parts of water, to make it a homogeneous mixture. | 6. | Do not add more than the required quantity of either gobar or water - doing so might affect the efficient production of gas. |

7. | When filling bio-gas plants with partition wall make sure that it is filled equally on both sides of the central partition wall, side by side up to the guide frame. | 7. | Do not fill the slurry unequally on both sides – it may cause the central wall to collapse. |

8. | Make sure that the mixture of gobar gas and water is free from soil or sand. | 8. | Do not allow any soil or sand particles to enter into the digester; otherwise, they will choke the inlet pipe at the bottom. |

9. | When the digester is full with the homogeneous gobar water mixture, place the gas holder on the central pipe of the guide frame. Keep the heavy duty gate valve closed. | 9. | Do not keep the gate valve loose; otherwise gas will escape from the plant unutilized. |

10. | Rotate the gas holder once or twice every day in order to break the scum. | 10. | Do not allow scum to form in the digester, otherwise the production of gas will stop. |

11. | Release the first full drum of gas to atmosphere to avoid any explosion. Bio-gas and oxygen mixture is explosive. | 11. | Don't use the gas initially produced as it may cause explosion due to the presence of oxygen. |

12. | As soon as gas starts accumulating in the gas holder, fit the pipeline from the gas holder to the kitchen. The gas produced should be utilized regularly. | 12. | The gas should not be burnt directly i.e., from the gas outlet even for testing purpose. |

13. | For efficient cooking, keep the approved burner preferably in the kitchen. | 13. | Do not light the burner in the open otherwise there can be considerable loss of heat. |

14. | Open the gas regulator cock at the time of its actual use. | 14. | Do not leave the gas regulator open when the burner is not in use. |

15. | Adjust the flame by turning the air regulator till a blue flame is obtained. This will give maximum heat. | 15. | Do not use the gas if the flame is yellow. Adjust the flame till it is blue in colour. |

16. | At an interval of 4-5 days drain out any condensed water which may have accumulated in the gas supply pipe. | 16. | Do not let any water accumulate in the gas pipe otherwise the required pressure of gas will not be maintained and the flame will sputter. |

17. | Periodically clean the gas holder from the outside with fresh water to avoid any crust formation. | 17. | Do not keep the gas holder dirty. |

18. | Store the slurry in a proper pit so that the liquid content may not leak through. | 18. | Do not make slurry pit more than 0.9 mtr. (3 ft.) deep |

19. | Check the outlet pipe periodically during the summer season to avoid clogging. | 19. | Do not allow the slurry to dry or cake at the end of the outlet pipe. |

20. | Repaint the gas holder (if it is of M.S. Sheet) from the outside every year with paint to prevent rusting. This will also prolong its life. | 20. | Do not allow the gas holder (if it is made of M.S. Sheets) to rust, this will develop holes resulting in leakage of gas. |

|

| |

Annexure- XI

Cost Benefit Analysis of KVIC Plant having an installed biogas generation capacity of 3 m³/day

(Amt. Rs.) |

| |

a. Capital cost |

|

Gas holder and frame | 4500 |

Piping and stove | 1750 |

Civil engineering construction (tank, inlet and outlet, etc.) | 10000 |

Total | 16250 |

b. Annual expenditure |

|

The interest on investment @ 9% p.a. | 1462.50 |

Depreciation on gas holder and frame @ 10% p.a. | 450 |

Depreciation on piping and stove @ 5% p.a. | 87.50 |

Depreciation on structure @ 5 % | 500 |

Cost of painting, once a Year | 350 |

Total | 2850 |

c. Annual income |

|

Gas 3m³ per day @ Rs. 2.30 / m³ for 315 days

( assuming initial 50 days of HRT) | 2173.50 |

Manure (6 tons, composted) with refuse 15 tons @ Rs. 200 / tonne | 3000 |

Total | 5173.50 |

d. Net annual income (b - c) | 2323.50 |

|

| |

| The net annual income of approximately Rs. 2300/- shows that the capital investment of Rs. 16250/- can be recouped in about seven years. There are also incidental advantages of hygienic improvement, the absence of smoke and soot in gas burning, convenience in burning, and the increased richness of manure. |

|

|

| |

No comments:

Post a Comment